18

Sep 2025

LRT and MRT: Structural Design Differences in Urban Transportation

LRT and MRT are both forms of urban rail but differ greatly in train technology, capacity, speed, and infrastructure. This…

18.09.2025

Engineering Practices

Posted on: Sep 26, 2025

16

CONTENTS

The Nuclear Power Plant Structural Design is a highly specialized field that demands unprecedented levels of safety and quality standards. Unlike conventional industrial facilities, the design and construction of a nuclear power plant are always subject to strict supervision by nuclear regulatory authorities, with exceptionally high requirements for safety, quality, and traceability throughout the project lifecycle. Even the smallest design or construction error can lead to serious consequences, which is why every aspect must be calculated with extreme caution and precision.

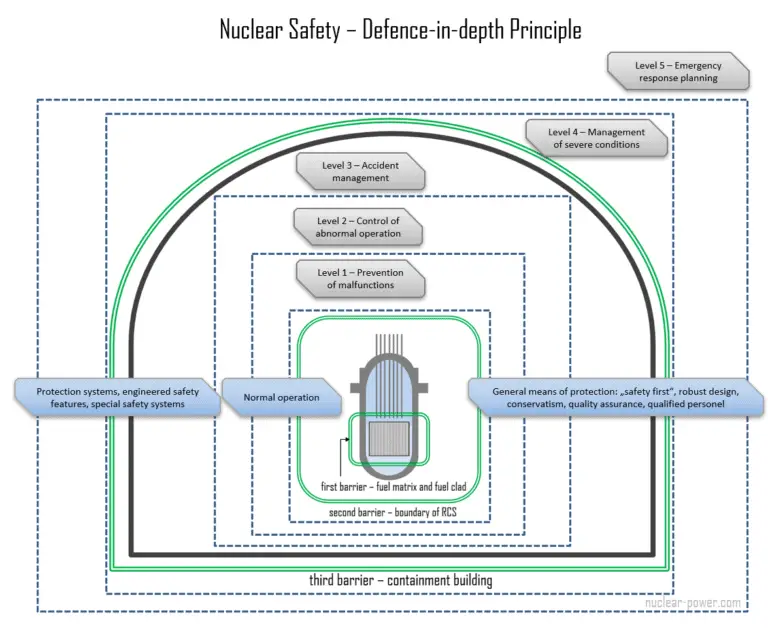

In Vietnam, this remains a relatively new field. According to the latest amendments to the Atomic Energy Law, in the absence of dedicated national standards, the structural design of nuclear power plants must follow international technical standards or those of foreign partners, in line with the International Atomic Energy Agency (IAEA) safety guidelines. The design must also comply with the principle of “defence-in-depth” — applying multiple safety barriers to protect people and the environment. In this approach, the structural system acts as the final physical barrier preventing radioactive release in the event of a severe accident. This creates extremely stringent demands on the nuclear power plant structural design to ensure absolute safety for communities and the environment over decades of plant operation.

Nuclear Safety – Defence-in-depth Principle

(Source: Nuclear Power)

A nuclear power plant consists of multiple complex facilities, typically divided into three main zones:

Nuclear Island: The most critical area, including the reactor building, safety systems, and the airtight containment structure surrounding the reactor. This zone requires the highest technical standards, with structures capable of withstanding earthquakes and maintaining safety even under severe accident scenarios. The reactor building is usually a reinforced concrete cylinder several meters thick, lined with a steel liner to prevent radioactive leakage.

Turbine Island: This area houses the turbine building, generators, condensers, and auxiliary equipment for power production. While safety requirements here are less stringent than in the Nuclear Island, the structures must remain durable, capable of withstanding vibrations from heavy machinery and indirect effects of accidents from the reactor area if they occur.

Balance of Plant (BOP): Comprising supporting structures such as switchyards, cooling systems, control buildings, maintenance centers, spent fuel storage, and radioactive waste facilities. Although these facilities do not directly contain nuclear materials, they must still be designed to meet high industrial safety standards, including seismic, fire, and radiation security requirements.

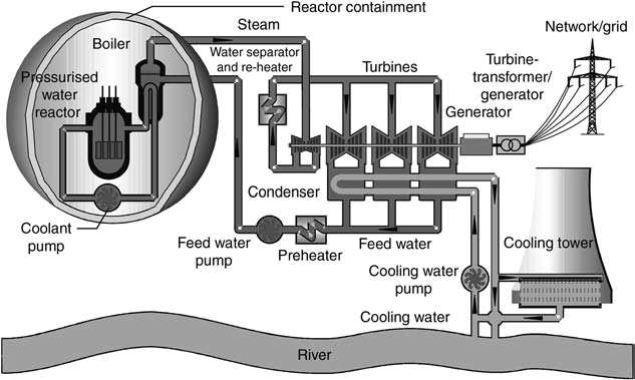

How a nuclear power plant works (pressurized water reactor model)

(Source: Meiswinkel, R.; Meyer, J.; Schnell, J. Design and Construction of Nuclear Power Plants. Ernst & Sohn, 2013.)

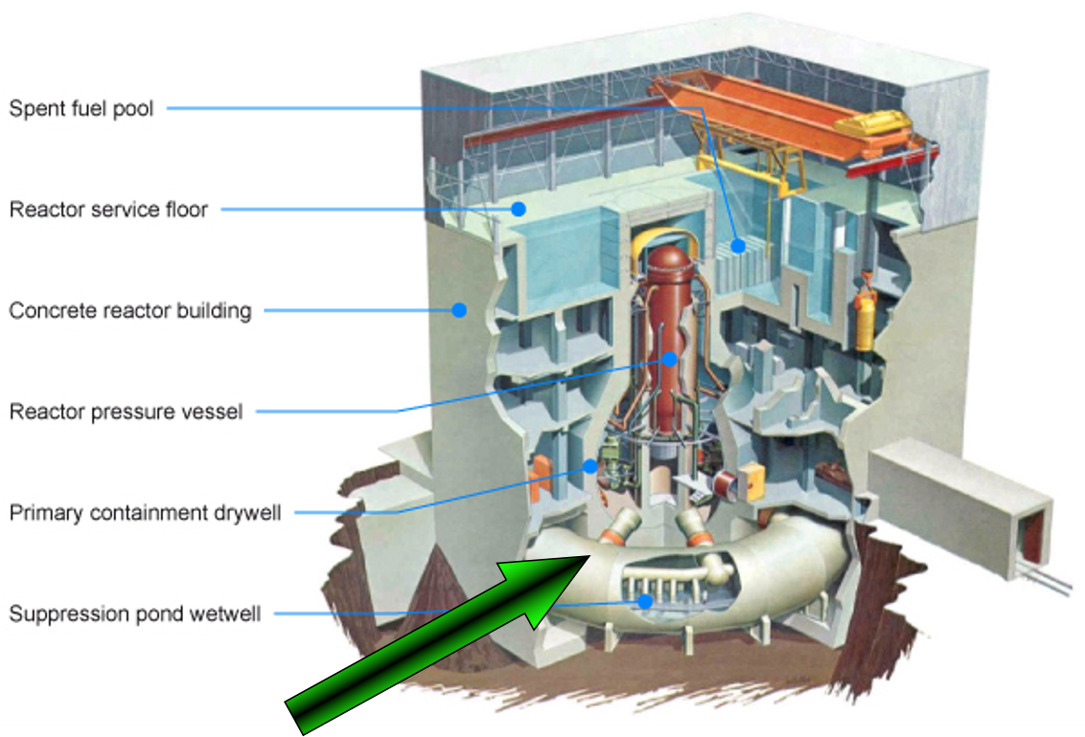

A particularly critical structural element is the containment building. For Pressurized Water Reactors (PWRs), the containment is typically a prestressed or reinforced concrete cylinder with a dome roof, lined inside with an airtight steel liner 6–10 mm thick. According to typical U.S. designs, the cylindrical walls are about 1.07–1.37 m (3.5–4.5 ft) thick, with a dome thickness of 1.1–1.2 m — sufficient to withstand internal pressure and heat loads during a Loss of Coolant Accident (LOCA). The containment must also resist high temperatures, radiation, and leakage limits under 10 CFR 50, Appendix J, ensuring its role as the final barrier against radioactive release. In other words, the containment building is the ultimate “fortress” protecting the environment in worst-case scenarios.

Main Components of a Boiling Water Reactor (BWR) Containment Building

(Source: Center for Domestic Preparedness)

Another defining feature of nuclear plant structures is their massive scale and loading conditions. The foundations of the reactor building and main structures are typically large mat foundations, several meters thick, designed to bear and distribute hundreds of tons from the reactor vessel, pressurizers, steam generators, and other heavy equipment. The design must ensure rigidity under dynamic and thermal loads while allowing for specialized construction methods to precisely install super-heavy equipment.

Compared with conventional thermal power plants, nuclear power plant structures are significantly more complex and demanding. Globally, only a limited number of engineering consultancies possess the capability and experience in this specialized sector. In Vietnam, structural design capacity for nuclear projects is still emerging through international cooperation, but much remains to be learned from global projects. This underscores the critical need for strict compliance with technical and safety requirements in nuclear power plant structural design.

The structural design of nuclear power plants (NPPs) must satisfy an extensive set of technical and safety requirements rarely encountered in other types of facilities. Key requirements include:

Resistance to earthquakes and extreme natural hazards:

In nuclear engineering, the governing load case is the Safe-Shutdown Earthquake (SSE). Structures classified as Seismic Category I must be designed to maintain full safety functions after an SSE. Beyond seismic loading, design also accounts for tornadoes and windborne missiles, severe storms, floods, and tsunamis, in accordance with the project’s licensing basis.

Ability to withstand severe internal accidents:

Designs must consider internal pressure–temperature loads from events such as a Loss of Coolant Accident (LOCA) and potential hydrogen combustion/explosions. The containment structure must maintain airtightness and protective functionality under these accident conditions.

Radiation shielding:

Structural design must calculate wall thicknesses and material compositions to shield radiation effectively. Heavy concretes (e.g., barite, magnetite, iron ore aggregates) are used to attenuate gamma rays, while boron-containing materials such as borated concrete or borated polyethylene are employed for neutron absorption at critical points. There is no universal “standard thickness”; each shielding requirement depends on specific project calculations.

Leak-tightness and containment integrity:

Spaces with potential radioactive release (such as containment) are lined with welded airtight steel liners, and all penetrations are sealed. Acceptance criteria follow 10 CFR 50, Appendix J leak rate testing:

ILRT/Type A (Integrated Leak Rate Test): Acceptance when Lam ≤ 0.75·La at Pa (design test pressure), as defined in plant technical specifications.

LLRT/Type B, C (Local Leak Rate Tests): Applied for penetrations, doors, and valves.

Periodic testing programs must comply with NEI 94-01, Option B, subject to regulatory approval.

Durability and long service life:

Designs must account for material aging and enable continuous monitoring during operation. In the U.S., nuclear plant licenses can be extended to 60–80 years under the Subsequent License Renewal (SLR) program, provided aging management programs are in place.

Strict fabrication tolerances and QA/QC programs:

Nuclear-grade construction requires rigorous quality assurance (QA) and quality control (QC) across the project lifecycle. For containment structures, deformation and airtightness must be controlled in compliance with ASME BPVC Section III, Division 2 (ACI 359). During operation, in-service inspections are mandated under ASME Section XI – Subsections IWE/IWL (IWE for steel liners, IWL for reinforced/prestressed concrete), with periodic checks as required by 10 CFR 50.55a. Tolerances and acceptance criteria must follow referenced codes and specific project requirements.

Safety under exceptional external events:

When specified in the licensing basis, projects must perform an Aircraft Impact Assessment (AIA) per 10 CFR 50.150 and NRC Regulatory Guide 1.217. Designs must also consider tornado and missile loads in line with NRC RG 1.76, as well as other external hazards such as industrial explosions or impact risks, as defined in project licensing documents.

To meet the stringent requirements outlined above, the structural design of nuclear power plants (excluding reactor core design) must comply with the highest levels of specialized standards and codes. Globally, a wide range of technical codes apply specifically to nuclear civil structures, including:

IAEA Standards and International Guidelines:

The IAEA SSR-2/1 (Rev.1) sets out safety principles for nuclear plant design, supported by Safety Guides covering safety classification, seismic design, construction, and quality management. The core principle is that structures must maintain safety functions under adverse loads (SSE, extreme winds, floods, impacts, etc.), while ensuring full traceability and change control throughout the project lifecycle.

U.S. Standards (ASCE, ACI, AISC, NRC, ASME, etc.):

Loads & Seismic Design:

ASCE 7 – General loading requirements

ASCE 4-16 – Seismic analysis for safety-related nuclear facilities

ASCE/SEI 43-19 – Seismic performance goals for nuclear SSCs (Structures, Systems, and Components)

Concrete Structures:

ACI 318 – Standard reinforced concrete design

ACI 349 – Reinforced concrete for safety-related nuclear structures (excluding containment under ACI/ASME 359)

ACI 350 – Concrete for environmental and liquid-containing structures

Steel Structures:

AISC 360 – General civil/industrial steel structures

AISC N690 (2018/2024) – Steel structures for nuclear safety-related facilities

Safety Classification:

NRC RG 1.29 (Rev.6) – Guidance for safety classification of structures; Category I structures must withstand SSE and maintain safety functions

Containment (when included in scope):

ASME BPVC Section III, Division 2 (ACI 359) – Rules for design, construction, and testing of prestressed or reinforced concrete containment with steel liner (pressure-retaining barrier)

10 CFR 50, Appendix J – Leak-tightness testing (Type A/B/C, ILRT/LLRT) with implementation guidance in NEI 94-01 (Option B)

ASME Section XI, Subsections IWE/IWL – In-service inspection requirements for steel liners (Class MC) and reinforced/prestressed concrete containment (Class CC)

Exceptional events: 10 CFR 50.150 and NRC RG 1.217 for Aircraft Impact Assessment (beyond design basis); NRC RG 1.76 (tornado & missiles) and RG 1.221 (hurricanes & missiles)

Note: ASME BPVC Section III, Division 1 applies to pressure boundary components (piping, vessels), not civil structures; Division 2 applies specifically to containment structures

Nuclear Quality Assurance:

10 CFR 50, Appendix B – QA criteria

ASME NQA-1 – Nuclear quality assurance program standards (latest revisions endorsed by NRC through RG 1.28)

European Standards (Eurocodes, AFCEN RCC-CW, etc.):

Many projects apply Eurocodes EC0/1/2/3/7/8 for general basis, loads, concrete, steel, geotechnical, and seismic design. For safety-related and containment structures, the AFCEN RCC-CW code (civil works for PWRs, evolved from ETC-C for EPRs) is used, combining Eurocode methodology with nuclear-specific requirements (SSE, containment leak testing ILRT/LLRT, ISI, etc.).

Vietnamese Standards (TCVN):

Where required by project owners, national standards are applied, such as:

TCVN 2737 – Loads

TCVN 5574 – Reinforced concrete

TCVN 5575 – Steel structures

TCVN 9386 – Seismic design (aligned with Eurocode 8)

TCVN 10304 – Pile foundations

These are typically cross-checked with international standards (ASCE/ACI/AISC/AFCEN) for safety-related or containment structures. Final selection and adaptation must be reviewed and approved by the national nuclear regulatory authority.

(Note: the TCVN references reflect local practice; exact application depends on bid documents and licensing requirements of the project.)

In addition to design standards, the selection of materials for nuclear power plant structures is highly specialized:

Special Concrete:

Concrete used in primary structures (reactor foundations, containment walls, spent fuel pools) is typically high-strength concrete (≥40 MPa) with high density and long-term durability. Mix designs may incorporate neutron-absorbing additives (e.g., boron oxide) to enhance radiation shielding. Heavy aggregates such as hematite or magnetite are sometimes added to shielding concrete to increase density and improve gamma-ray attenuation.

For mass concrete placement, Self-Compacting Concrete (SCC) is widely adopted in advanced nuclear countries (e.g., China, South Korea) as it eliminates the need for vibration, flows easily into complex formwork, and produces high-quality structural surfaces. The IAEA recommends that emerging nuclear countries like Vietnam should standardize SCC technology for future projects. Large concrete pours are often monitored with embedded temperature and stress sensors to control hydration heat and prevent thermal cracking.

Structural Steel and Reinforcement:

Steel components (e.g., steel containment domes, heavy equipment support frames) must use high-quality, radiation-resistant steel with good ductility and fracture toughness. The containment steel liner is typically fabricated from low-carbon steel plates of large dimensions, welded on-site to form a continuous airtight barrier. Reinforcing steel in concrete must have strong bond characteristics and low impurity levels to resist corrosion. Reinforcement density is extremely high in critical nuclear structures — for example, containment walls often feature dual-layer dense rebar meshes with spacing <15 cm, or prestressing tendons tightly wound to compress the concrete, enhancing load-bearing capacity and crack resistance.

Fireproofing and Thermal Insulation Materials:

While concrete itself has inherent fire resistance, nuclear steel structures require additional protection using specialized fireproof coatings or panels, ensuring several hours of fire resistance without loss of structural integrity. Critical safety-related equipment rooms are also fitted with thermal insulation and fire barriers so that if one system experiences fire, adjacent systems remain unaffected — reflecting the defence-in-depth philosophy.

In summary, both design standards and material choices for nuclear power plant structural designs are applied at the highest safety margins to ensure stability and secure operation over decades. The combination of strict codes and specialized materials enables vital structures such as containment to withstand extreme mechanical loads while also serving as effective radiation barriers — reinforcing public confidence in the safety of nuclear power plants.

To meet the demanding requirements and standards of nuclear power plants, structural engineers must apply a range of advanced design and construction solutions. These approaches ensure maximum safety while also optimizing construction schedule and quality. Key solutions widely used in modern nuclear projects include:

Advanced Analysis and Simulation:

From the early design stage, engineers use full 3D finite element models to calculate critical load combinations (SSE, LOCA, extreme winds, etc.). Nonlinear behaviors such as concrete cracking, steel yielding, aircraft impact, and hydrogen explosions are simulated using specialized software like ANSYS, ABAQUS, and LS-DYNA. Soil–structure interaction (SSI) is also modeled to design foundations suited to site-specific geotechnical conditions.

Seismic Isolation and Energy Dissipation Systems:

Technologies such as base isolation and dampers are applied to reduce seismic forces and mechanical vibrations transmitted to structures. Several Small Modular Reactors (SMRs) and next-generation reactors are expected to integrate these systems, following IAEA SSG-67 and research such as Manish Kumar & A.S. Whittaker (2014), Soil Dynamics and Earthquake Engineering.

Building Information Modeling (BIM):

BIM integrates structural, mechanical, and piping systems into a unified 3D model, extended with time (4D) and cost (5D) dimensions. This enables early clash detection, minimizes rework during construction, and optimizes multidisciplinary coordination. Projects like Olkiluoto-3 (Finland) and Hinkley Point C (UK) have demonstrated the effectiveness of BIM in nuclear design.

Modular and Prefabricated Construction:

Modularization is a key solution for accelerating schedules and improving quality. The principle is to divide the plant into modules or large prefabricated components manufactured in factories under strict quality control, then transported and assembled on-site. Examples include containment wall panels with integrated steel liners, precast reactor foundation blocks, safety pump room modules, and pipe/cable assemblies.

At the Barakah NPP (UAE), over 50% of work volume was modularized, enabling the parallel construction of four units efficiently. In China, standardized modular design has enabled the construction of two reactors within just five years — a remarkable achievement. Modularization not only shortens construction time but also reduces on-site errors, thanks to factory-level precision and quality.

Strict Quality Assurance and Digital QA/QC:

Comprehensive QA/QC programs cover the entire process from material production to welding and concrete pouring. For example, all containment liner welds are 100% inspected by NDT (non-destructive testing), while concrete samples undergo strength and permeability testing. Today, advanced methods such as Digital Twin and PLM (Project Lifecycle Management) systems are increasingly used to monitor structures in real time, ensure data traceability, and improve reliability in quality management.

Specialized Construction Equipment:

Large tower cranes, self-propelled heavy transporters, robots for radioactive environments, and drones for progress monitoring are deployed to enhance accuracy, safety, and efficiency. Some countries, including South Korea and Russia, have developed dedicated heavy-lift vehicles specifically for reactor installation, enabling precise positioning of super-heavy components in constrained spaces.

A historical photograph from a U.S. nuclear power plant (1970s) shows the construction of a reactor building with massive reinforced concrete walls, while the reactor pressure vessel (a large cylindrical component) is lifted into place using a specialized crane. The process highlights the extraordinary scale and complexity of nuclear power plant construction.

(Source: U.S. Department of Energy; credit via The Equation – Union of Concerned Scientists)

Thanks to these solutions, modern nuclear projects achieve unprecedented levels of safety and quality. However, this also comes with substantial cost and schedule implications — an inevitable trade-off when prioritizing nuclear safety. Global experience, such as the Olkiluoto-3 project in Finland which suffered significant delays due to design and quality management issues, demonstrates the importance of not only advanced technical methods but also effective project management, regulatory coordination, and contractor collaboration, as emphasized by the IAEA.

The ultimate goal is to deliver nuclear facilities that operate safely and reliably for decades while supporting the global pursuit of clean and sustainable energy.

Nuclear power plant structural design is an exceptionally complex task, requiring structures to withstand rare accident loads, ensure radiation safety, and achieve flawless construction quality. To meet these requirements, the industry applies state-of-the-art solutions such as advanced simulation, specialized nuclear-grade materials, modular construction, BIM integration, and digital QA/QC.

As Vietnam considers restarting its nuclear power program, mastering these standards, requirements, and technologies will be the decisive factor for success. With thorough preparation in human resources, technology, and regulatory frameworks, Vietnam’s future nuclear power plants can fully comply with international benchmarks, operate safely and efficiently, and contribute to long-term national energy security.

For more information on Pontech’s expertise in nuclear power plant structural design, including service scope and case studies, please contact us directly. We will provide details in accordance with our confidentiality policy.