Light Rail Transit (LRT) is emerging as a green, efficient solution for urban mobility. From a structural engineering perspective, LRT shares many features with metro and tram systems, yet has critical differences that shape structural design. This article explores LRT structural design—from technical overview and key structural components to urban construction challenges and new technology trends.

A light rail train operating on an elevated concrete viaduct in Asia. LRT typically uses lighter rolling stock than metro, enabling slimmer viaducts and tighter curve radii (illustrative image).

1. Structural Engineering Overview of LRT

Light Rail Transit is an urban rail system with lightweight rolling stock and medium passenger capacity, operable on elevated, at-grade, or underground alignments. LRT is often considered the middle ground between traditional tramway and heavy metro. Structurally, this means LRT bridges, tunnels, and stations are designed for loads smaller than metro but higher than tramway. LRT structural design must meet distinct requirements: lightweight yet durable, compatible with track and rolling stock, and well-suited to constrained urban environments.

Key strengths of LRT:

-

Flexible alignment options (elevated, at-grade, or underground)

-

Moderate axle loads → slimmer, more economical structures than metro

-

Lower capital expenditure than metro (about 40–60%)

-

Higher capacity than buses/tram in many contexts

1.1. How LRT Differs from Metro/Tramway in Design Parameters

From a structural viewpoint, light rail transit LRT, metro, and tramway (visit the following link to learn more about the Differences Between LRT and MRT) differ in basic parameters such as axle loads, minimum curve radius, maximum gradient, and structure gauge. These directly affect bridge, tunnel, trackbed, and station solutions.

| Design Parameter |

Tramway |

LRT |

Metro |

| Max axle load (tonnes) |

~8–10 |

~10–12 |

~14–16 |

| Min horizontal curve radius |

~25 m (can be smaller) |

~50 m (can be ~25 m at low speed) |

~120 m (preferably > 250 m) |

| Max longitudinal gradient |

~6–7% |

~6% |

~4% |

| Structure gauge (width × height) |

~2.4 × 3.5 m |

~2.65 × 3.8 m |

~3.0 × 4.0 m |

Table: Indicative design parameters influencing structures for tramway, LRT, and metro. Sitting between tramway and metro, LRT guideway structures can be more compact than metro yet stiffer than tramway.

1.2. LRT in Contemporary Transport Planning

Globally, light rail transit LRT has grown as a “green answer” for cities. By 2021, UITP reported roughly 16.000 km of LRT in 404 cities, serving 14.662 million passenger trips.

LRT appeals to mid- to large-size cities thanks to lower cost than underground metro (some Canadian reports show LRT costs at roughly half of a metro tunnel) while offering higher capacity than buses and low emissions (electric traction). Experts regard LRT as a safe, accessible backbone that complements wider public transit networks and supports green corridor design along the route.

In Vietnam, transport plans in Hanoi and Ho Chi Minh City already mention LRT as supplemental urban rail lines (after metro networks take shape). A recent proposal envisions a ~100 km HCMC–Tay Ninh LRT corridor along the Saigon River to strengthen regional connectivity and relieve existing infrastructure. This signals strong potential for LRT in Vietnam—and a need to prepare international-standard structural design capabilities.

2. Main Structural Components of Light Rail Transit LRT

2.1. Trackform (Superstructure Track Support)

In cities, LRT trackform is rarely uniform. A single corridor can include three or four interfaces:

-

On viaducts: Direct fixation—rails fastened to concrete deck or plinths with resilient anchors

-

In tunnels / vibration-sensitive zones: Floating slab—heavy concrete slabs on rubber/spring bearings (a mass-spring system) for vibration isolation

-

At-grade in streets: Embedded track—rail encapsulated in elastomer and flush with roadway for mixed traffic

-

Depots / peri-urban: Ballasted track—traditional ballast for economy

The golden rule is maintaining relatively uniform vertical stiffness along the line so trains ride smoothly, with careful interface detailing to avoid stiff “steps” that cause impact. For light rail transit LRT, the moderate loads make direct fixation and embedded track particularly attractive: slim structural depth, precise geometry control, and lower maintenance. For hospitals, universities, and labs, floating slab helps cut low-frequency ground-borne vibration beyond what standard rail encapsulation can achieve.

2.2. LRT Viaducts & Bridges: U-Girders, Box Girders, and Composite Bridges

Viaducts are the spine of many urban LRT lines. U-girders are popular for good reasons: with rails sitting inside the “trough,” the structural depth is reduced (vs. top-of-deck rails), improving clearance beneath without raising the entire profile. The side webs act as natural parapets/sound walls, improving safety for derailments and giving a clean urban silhouette. With full-span precast erection by mobile cranes, U-girders minimize on-street disruption—vital in dense neighborhoods.

Still, U-girders aren’t a cure-all. Pre-stressed concrete box girders remain the go-to for longer spans or interfaces with existing highway structures. Where ultra-light construction, river crossings, or special spans are required, steel–concrete composite girders offer broad design latitude and rapid erection—at the cost of more stringent steel maintenance.

In practice, successful projects often blend solutions: U for tangents, box through complex junctions, composite over obstacles—each used where it shines.

-

-

Line 3 Nhon–Hanoi Station adopts compact precast U-girders, delivering a slimmer profile and improved urban aesthetics.

-

-

Cat Linh–Ha Đông LRT uses pre-stressed concrete box girders with closed-box sections, creating a more solid, less slender appearance from street level.

Pi-girders are also widely used. On LRT-1 Cavite (Manila), the contractor used an overhead launcher to erect 203 Pi spans—1–2 days per span, a Philippines first—accelerating schedule and avoiding ground-level traffic impacts.

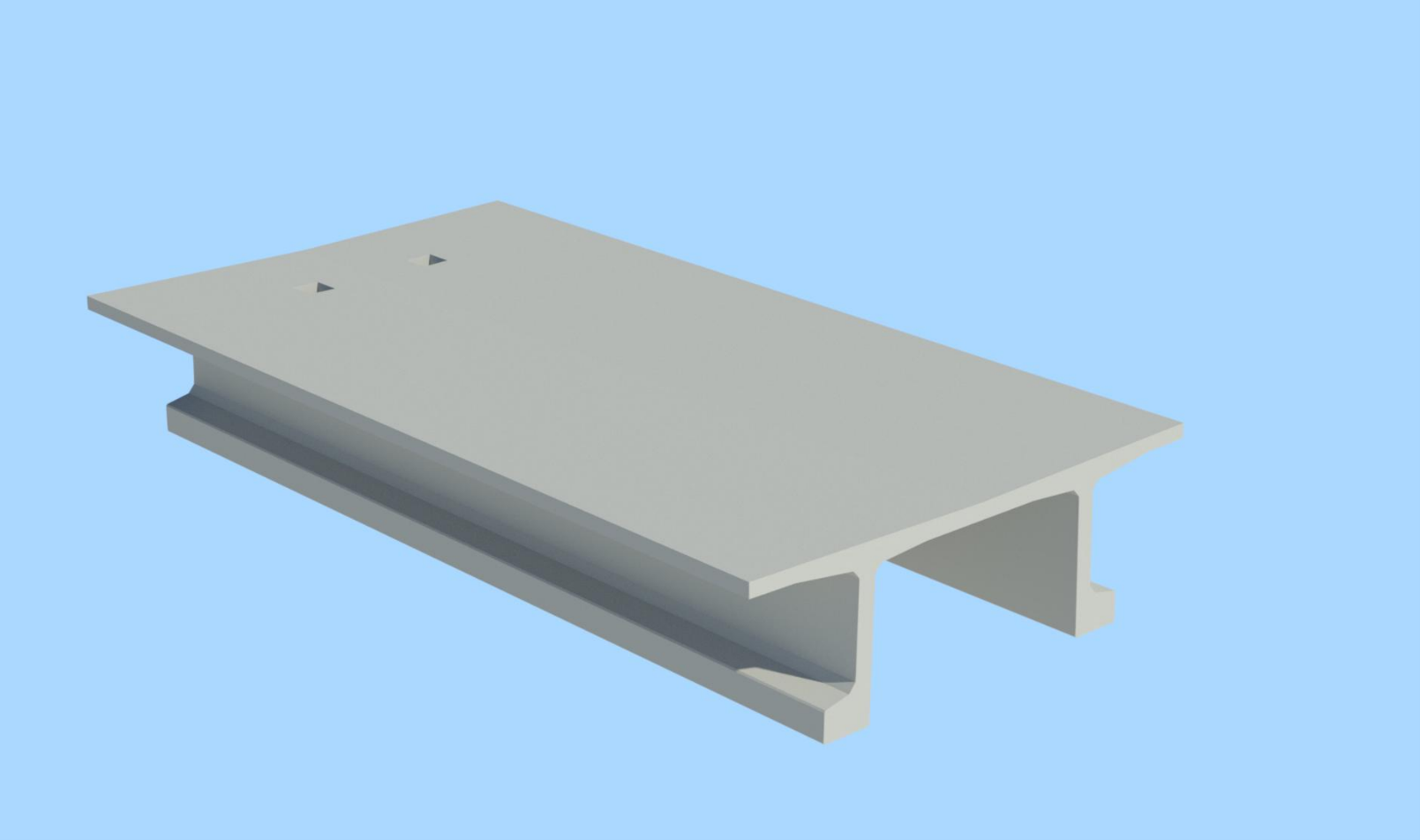

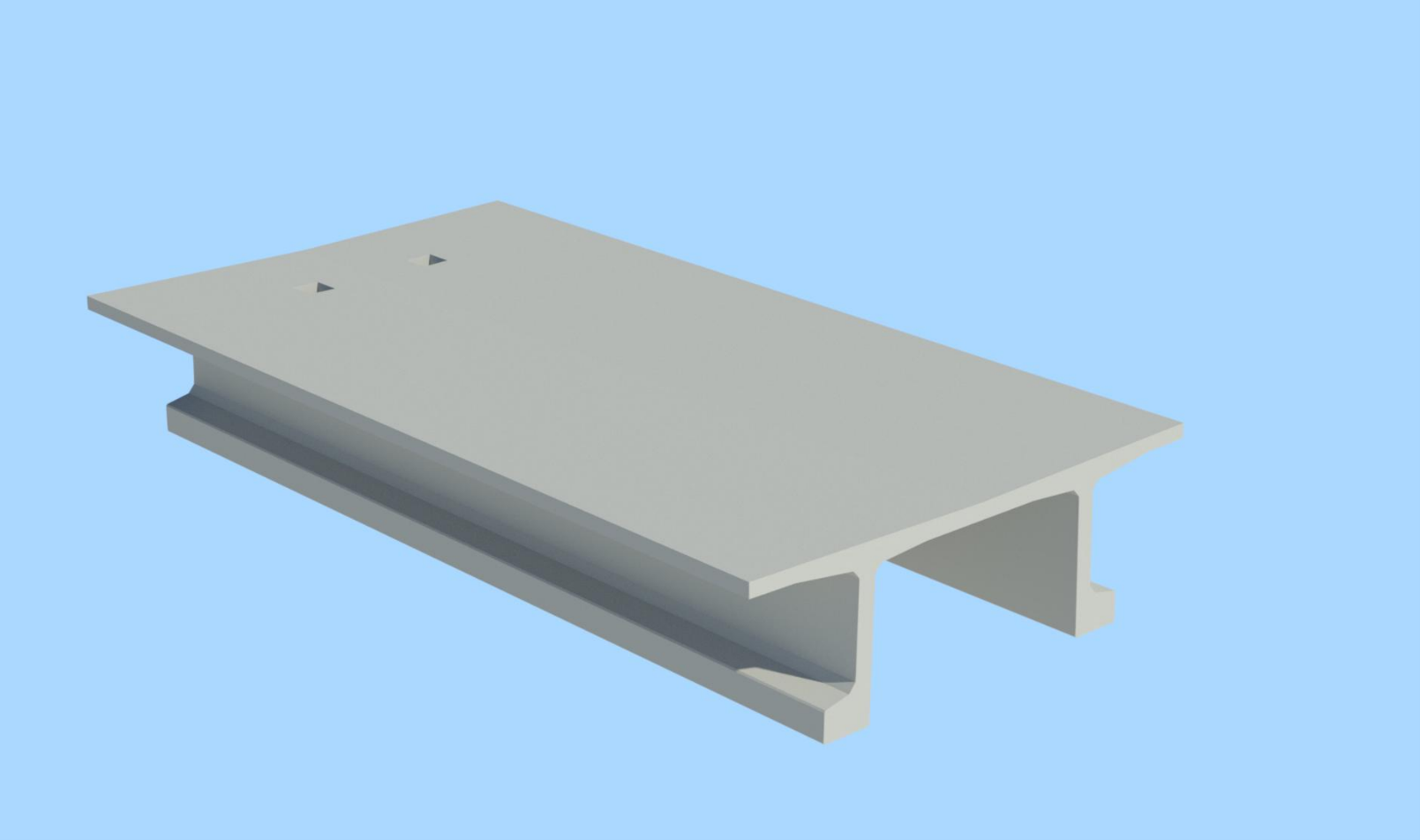

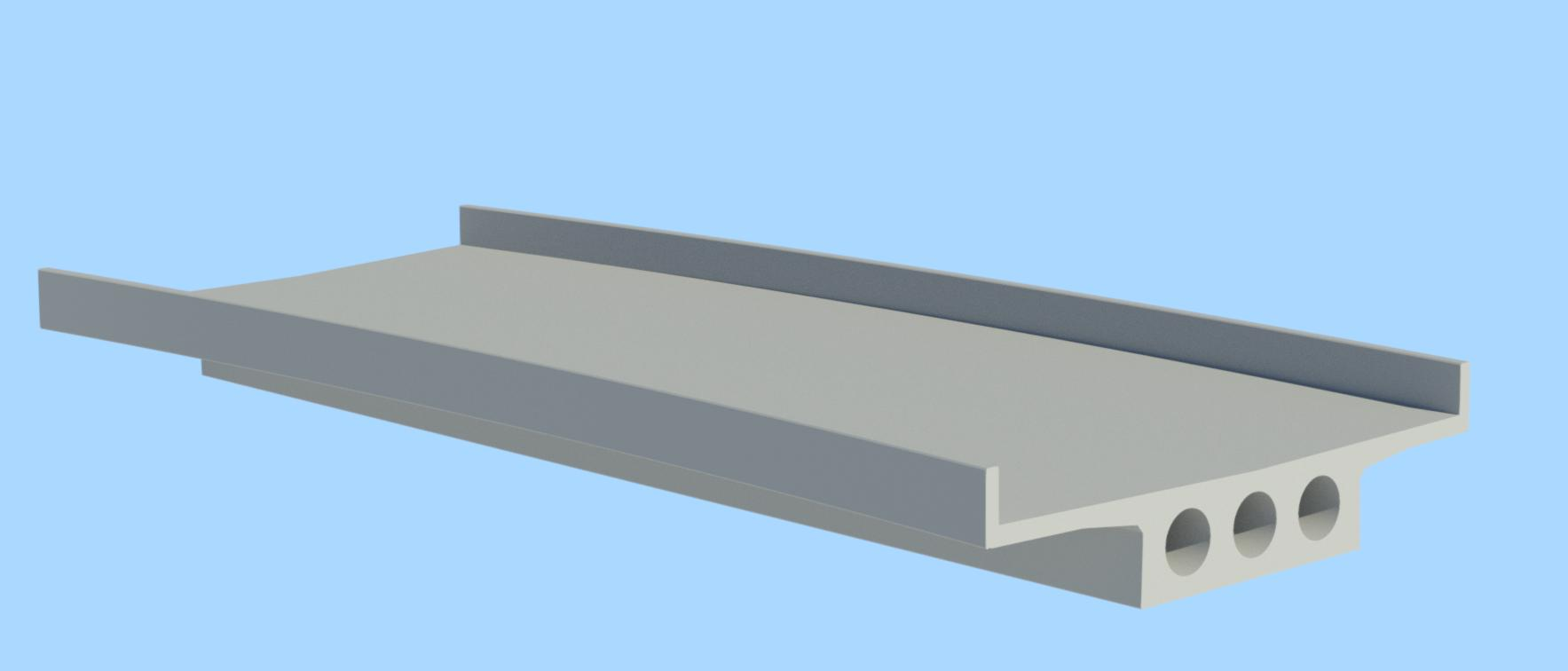

Pi-girder in LRT bridge design. (Credit: Pontech)

Erecting an LRT viaduct with precast Pi-girders. All girders and piers are factory precast and assembled using an overhead launching gantry (orange) to avoid disrupting traffic below. This method was successfully applied on the LRT-1 Cavite (Manila) line with 203 spans. (Credit: Light Rail Manila Corporation)

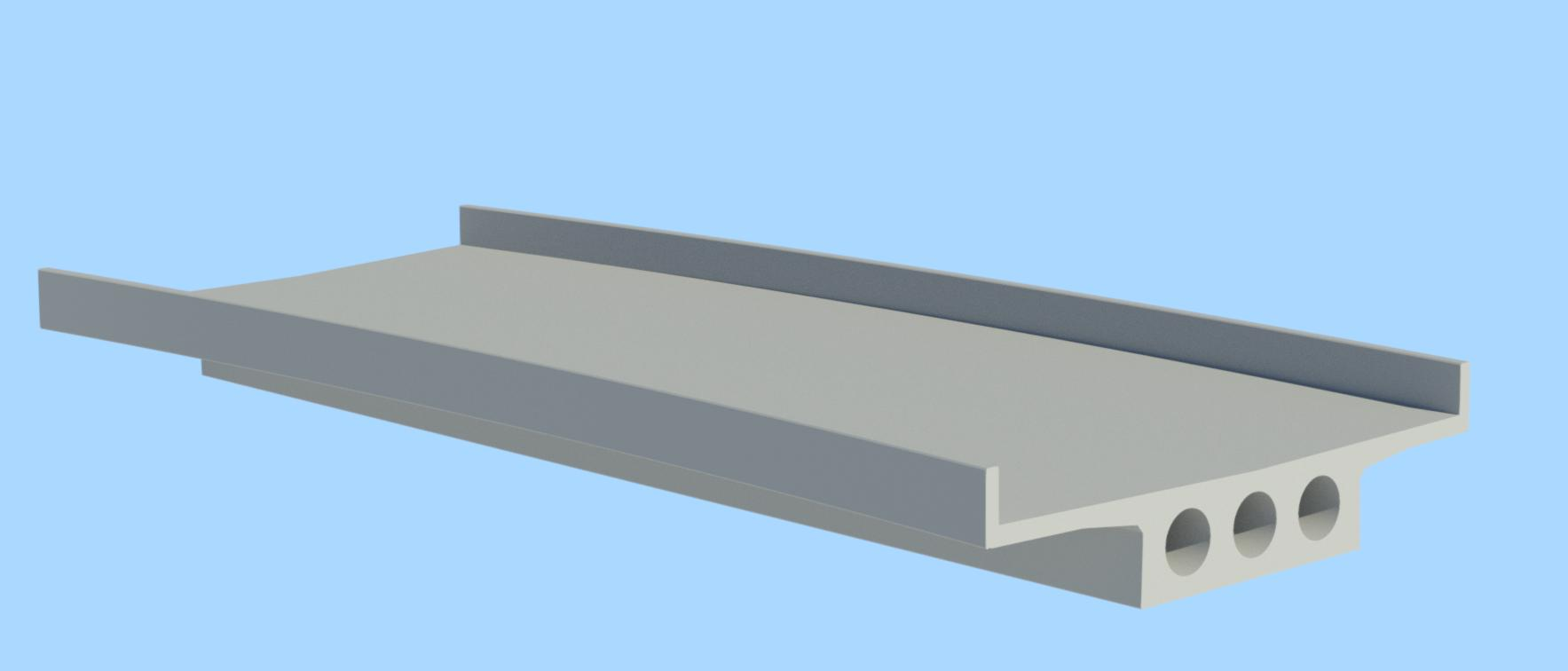

Beyond these, slab bridges suit short spans, and rigid frame bridges can help at low-clearance crossings. On the LRT-1 Extension (Manila), Pontech engineers used voided slab spans at the interface with the existing line and Pi-girders on new sections.

Voided slab bridge in LRT bridge design. (Credit: Pontech)

Bottom line: choose the optimal girder type (U, Pi, slab, box, composite) by span, loads, and constructability. While precast U-girders are trending for efficiency and urban aesthetics, engineers must still verify strength, deflection, vibration, and track–structure compatibility for every option.

2.3. Tunnels and Underground Works (Where Applicable)

Light rail transit LRT often favors surface or elevated alignments for economy, but central districts, obstacles, or urban-design considerations can push underground solutions. Fundamentally, LRT tunnels resemble metro tunnels: TBM for deep bores with precast segment linings; cut-and-cover for shallow sections and stations. LRT’s smaller structure gauge can trim tunnel diameter, but core design issues remain: waterproofing, settlement control, lining–invert–trackform interfaces, and egress must all meet rail standards. Transitions between tunnel–viaduct–at-grade require smooth stiffness changes to avoid dynamic “steps.

Inside a precast concrete LRT tunnel during trackform installation. The circular segmental lining and cast concrete invert are in place, ready for rail fastening. The tunnel envelope provides clearance for LRT trains and side egress on both sides. (Credit: Sound Transit)

2.4. Stations and Auxiliary Structures

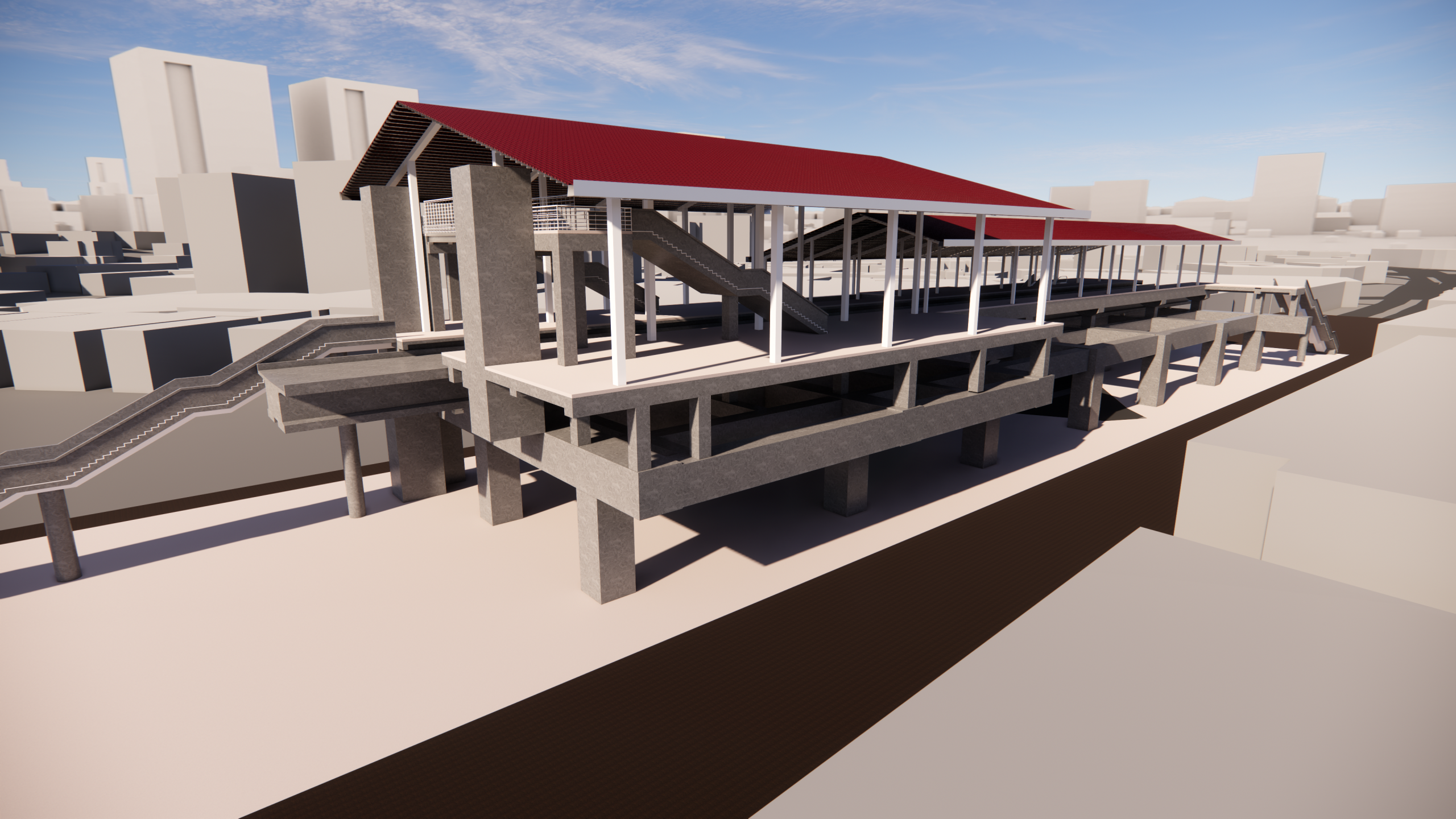

Elevated LRT stations are effectively buildings on the line, carrying concentrated crowds, wind on large roof areas, and train-induced vibration.

-

Frames/slabs: reinforced concrete or prefabricated steel per schedule strategy

-

Roofs: lightweight long-span systems (steel trusses, UHPC shells, composite panels) with reliable connections and expansion joints

-

Platforms & concourses: adequate stiffness to avoid perceptible “bounce” during train dwell/acceleration

A subtlety is the line–station interface. Where stations sit on viaducts, the underlying spans often need beefed-up sections and careful frequency control, as dynamic loading differs from plain guideway. At station approaches, trackform usually includes rail expansion gaps and fastener stiffness tuning to decouple vibrations and thermal movements between bridge and architectural frame.

Beyond stations, an LRT corridor includes systemwide facilities: depots & maintenance workshops, traction power substations (TPSS) and distribution, OCS/earthing, signal & telecom rooms, and the OCC. These demand specific foundations, electrical safety, structure gauge, and noise–vibration control, coordinated with the guideway design.

-

-

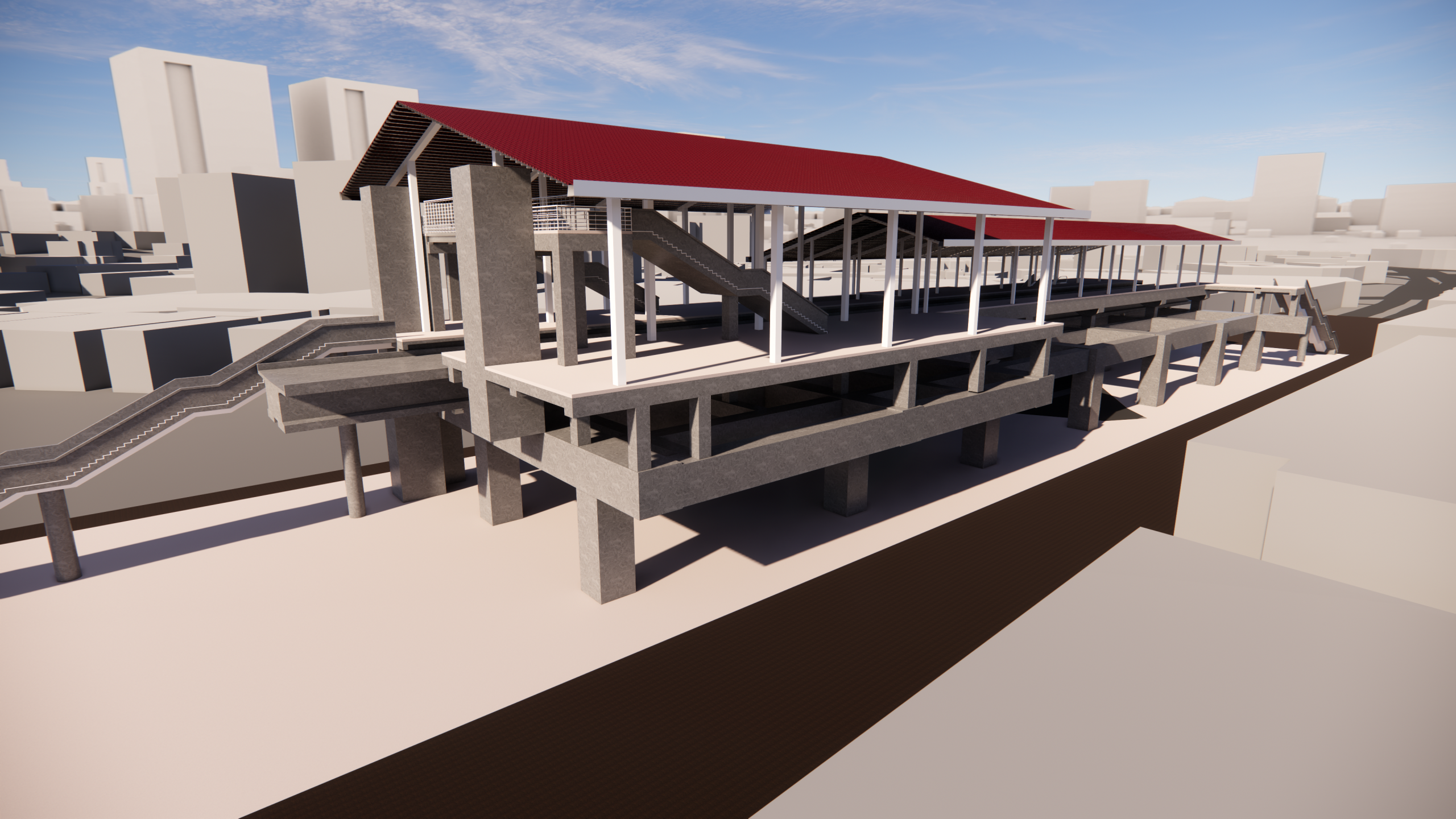

LRT-1 Manila Extension station.

-

-

LRT-1 Manila station – 3D model. (Credit: Pontech)

2.5. Foundations & Geotechnical Works: Bored Piles, Barrettes, Diaphragm Walls

LRT loads are “light,” but the geotechnical engineering is serious. Large-diameter bored piles are common for pier/station columns, handling axial and lateral loads in tight sites; where high lateral resistance and differential settlement control are needed, barrettes (rectangular shafts) provide superior sliding/rotation resistance. For shallow underground/cut-and-cover, diaphragm walls act as both excavation support and permanent structure. On at-grade sections, subbase quality and weak ground treatment must prevent settlement that would distort track geometry.

Two crucial design points:

-

Near existing buildings—allow for tight workspace and adjacent settlement. Mono-pile solutions can minimize urban footprint.

-

Longitudinal loads—account for braking, centrifugal, and seismic effects (for seismically active regions).

Pontech’s work on the LRT-1 Manila Extension (Philippines’ Pacific Ring of Fire) favored larger pile diameters and higher concrete strengths to meet demanding seismic actions.

2.6. Track–Structure Interaction (TSI) & Rail Thermal Expansion

On LRT viaducts, rails and girders are two elastic systems vibrating together, each with its own thermal movement. With continuous welded rail (CWR) over multiple spans, bridge longitudinal movements from temperature and train braking/traction can push/pull the rail, generating significant axial stresses. Poorly managed TSI risks sun-kinks or overstressed fasteners—threatening safety.

Model TSI explicitly (thermal, longitudinal train loads, wind, seismic) and check both rail limits (axial stress, relative displacement) and bridge effects (bearing and fixed-pier forces).

A typical TSI toolkit includes: rail expansion joints at long bridges or high thermal ranges; fastener stiffness that holds geometry yet allows controlled slip; well-defined bearings (fixed bearings resist longitudinal/lateral loads at intended locations; sliding bearings sized appropriately); and consistent placement of architectural–bridge–track expansion joints to simplify inspection and maintenance. Done right, rails ride smooth while the bridge “breathes” as designed.

3. Engineering Challenges in Dense Urban Settings

3.1. Vibration–Noise & Floor Motion

Train-induced vibration spans frequencies perceptible to humans (< ~80 Hz) and can affect nearby buildings. In the city, ride comfort and noise matter as much as throughput. There’s no single “on/off” fix—effective solutions are multi-layered:

-

At the source: rail grinding, curve lubrication to cut squeal; rail dampers for high-frequency modes;

-

Through the trackform: resilient fasteners, rubber-encased sleepers, under-sleeper mats; for tougher cases, floating slab systems (mass–spring) that absorb low-frequency energy;

-

Along the line: sound walls—often glazed—protect living quality without visual clutter. U-girder side webs naturally act as partial sound barriers, reducing need for extra walls.

Installing a floating slab block for tunnel track. The red slab uses a heavy aggregate (iron-ore) concrete mix and is mounted on circular rubber bearings beneath. Each ~5-ton mass–spring unit absorbs train-induced vibration, protecting the surrounding environment. (Credit: Sound Transit)

3.2. Clearances and Construction in Tight Sites

Fitting a rail corridor into crowded streets is non-trivial. Structure gauge must be checked to the centimeter around moving stock—door edges, parapets, lamp posts, even residential balconies. On viaducts, overall deck width must suffice for rails, maintenance walkways, and parapets without over-occupying the visual corridor; U-girders help minimize total width.

Beyond operational clearances, construction clearances matter: nighttime lifting of full spans over intersections, installing piers next to buildings without cracking, and staging just-in-time fabrication yards. Modern strategies shift work to factories: precast spans, piers, pier caps, even modular roofs and stairways; on site, overhead launchers or specialized cranes do quick assembly. The ideal day becomes “night install—morning traffic open,” limiting disruption to urban life.

4. The State of LRT Today

As noted, Light rail transit LRT is experiencing a renaissance worldwide as a sustainable choice. With urbanization and decarbonization goals, many cities are (re)investing in LRT after years focused on metro. Structurally, LRT codes and guides are maturing, drawing from both railway and highway standards.

UITP (2021) indicates an average of 6–7 new LRT lines opening annually. The global LRT market was about US$101B in 2023, projected to reach US$212B by 2031. Demand is rising for design consultancy, standardization, and knowledge exchange. Sector events and publications—such as the Track Design Handbook for Light Rail Transit (US) and UIC guidance—now address LRT explicitly, complementing heavy-rail-centric standards.

5. Trends & Technologies in LRT Structures

5.1. Prefabricated & Modular Viaducts and Stations

Prefabrication & modular construction (DfMA) now dominate infrastructure delivery—and LRT is no exception. The aim is to shift work from the street to the factory, producing high-quality components for rapid on-site assembly. Typical candidates include U-girders, Pi-girders, segmental box units, pier caps–piers–pile caps, and even station floor/roof modules. BIM-4D-5D drives ID tagging, lift points, weights, erection sequences, and logistics from day one. The payoff: less dust, less noise, less congestion, and week-by-week measurable progress—sites that feel like assembly lines rather than construction zones.

5.2. Next-Generation Vibration–Noise Mitigation

Alongside proven methods, new tech is making LRT corridors library-quiet: tuned polyurethane pads, steel-spring mass–spring systems, lightweight composite rail dampers, even wheel-rim absorbers—each targeting specific frequency bands. On the ops side, IoT sensors across bridges, track, and adjacent buildings stream data; when thresholds trigger, operators automatically reduce speed, schedule rail grinding, or adjust lubrication. Technology doesn’t replace good design—but it turns good design into a self-aware system.

Additionally, BIM and digital QA now run end-to-end on most projects—including LRT structural works—to optimize coordination, cut errors, and maintain consistent quality during construction.

6. Conclusions

Light Rail Transit LRT is poised to become a mainstay of urban transport in Vietnam. Mastering structural design for LRT equips us to deliver these projects efficiently. Structurally, LRT brings clear advantages (lighter loads; slimmer, more elegant structures than metro) while posing subtle technical demands: safety in tight spaces, smooth track–structure interaction, vibration–noise control, and rapid modular construction in busy streets.

With experience in viaducts (U/Pi/voided slab/box), elevated stations, tunnel/viaduct trackform, and bored piles–barrettes–diaphragm walls in complex urban geologies, plus BIM & Digital QA from design through shop drawings and modular erection, Pontech is ready to be your structural partner for LRT projects in Vietnam and the region. Put the engineering in the right place, and light rail will deliver urban journeys that are smooth, safe, durable, and elegant.

Planning an LRT Project?

Let’s discuss your goals. Pontech’s structural engineering team can help you define optimal structural options and a modular erection strategy tailored to tight urban sites—so construction is clean, fast, and predictable.