22

Sep 2025

Prefabricated Rebar Cage Solution – Optimizing Concrete Wall Construction

Explore the prefabricated rebar cage solution: shorten schedules, reduce labor, and improve quality for concrete walls and complex works such…

22.09.2025

Trends & Technology

Posted on: Aug 07, 2025

992

CONTENTS

Artificial Intelligence (AI) is gradually penetrating various engineering fields, including structural design. Some believe AI will revolutionize structural workflows, allowing engineers to optimize structures more quickly and efficiently. However, many others remain skeptical, questioning whether AI in structural design truly delivers practical value or is simply a fleeting marketing trend.

This article, compiled by Pontech from multiple professional sources and viewpoints – including real-world observations and the technical insights of Pontech – aims to analyze the current status of AI applications in structural design across four main sectors: (1) Bridges and viaducts, (2) Railway stations and auxiliary facilities, (3) Civil & industrial buildings, and (4) Nuclear power plant structures. It provides structural engineers, students, contractors, consultants, and project managers with a clear view of both the potential and limitations of AI in this field.

The bridge design field has long embraced structural optimization algorithms, which are the forerunners of today’s AI applications. For over a decade, industries like automotive and aerospace have widely adopted shape optimization techniques (such as topology optimization) to reduce weight while ensuring structural strength. Now, similar techniques are being applied to bridge structures, enabling engineers to explore innovative configurations beyond conventional intuition. Generative AI design can “reverse” the traditional design workflow: instead of engineers proposing a design and then checking its strength, we can input objectives and boundary conditions, and let AI propose solutions that meet the criteria without going through multiple trial-and-error cycles.

A typical example is the Wiborada pedestrian bridge project in Switzerland. The research team at ETH Zurich developed an AI assistant for bridge design and tested it on the Wiborada bridge concept in St. Gallen (in collaboration with the consultancy Basler & Hofmann). As a result, AI generated several feasible bridge design solutions and performed sensitivity analysis to identify which parameters most affect structural safety, cost, and sustainability.

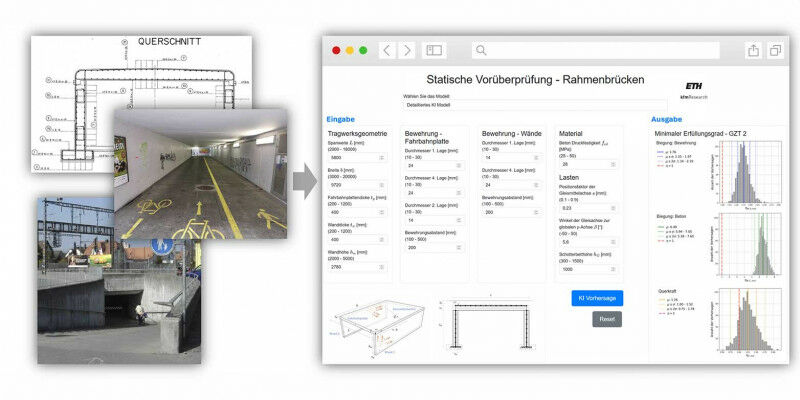

AI-powered web tools allow users to input data from an existing bridge and instantly predict its static load-bearing capacity—fully compliant with Swiss standards. (Illustration: Sophia Kuhn / ETH Zurich)

The engineering team greatly valued these results but emphasized that AI serves only as a support tool, not a replacement for engineers. AI can propose technically sound solutions, but the shapes may sometimes be unconventional; in such cases, humans must still assess constructability and long-term durability. AI is not a “one-click” tool that produces a perfect solution—it requires ongoing interaction with engineers throughout the design process. This shows that AI indeed opens new optimization paths, but the role of engineers remains indispensable.

The Wiborada pedestrian bridge in St. Gallen was used as a case study to develop a new AI assistant. (Source: Basler & Hofmann AG design team, Nau2, and dgj Landscape)

Besides proposing new designs, AI also supports the evaluation of existing bridge structures. For instance, Sophia Kuhn and colleagues at ETH Zurich developed an AI model to assess the safety of rigid-frame reinforced concrete bridges—a common type in the Swiss railway network. With a single click, this AI system can indicate which bridges may pose structural safety risks, helping engineers prioritize inspections and retrofits in time to prevent incidents. AI can even suggest whether it is necessary to run advanced structural analyses (which are often time-consuming)—a decision that is often difficult for engineers due to uncertainty about whether detailed simulations would yield significantly different results from simpler methods. Thanks to AI, engineers can save time and costs by knowing when to invest in in-depth calculations.

These applications show that AI is helping extend the lifespan of existing bridges while supporting more optimal designs for new ones—a practical value, not just a theoretical concept.

In summary, in bridge design, AI has already begun to make a real-world impact. Research and industry collaborations show that AI can propose creative, optimized bridge structures in terms of material usage, cost, and sustainability. More importantly, AI frees engineers from excessive trial-and-error design phases, allowing quicker decisions based on machine-generated data analysis. That said, experience and engineering judgment are still decisive in verifying and choosing the final design. AI in bridge design is not just a flashy trend—it is gradually becoming a practical assistant, as long as we clearly understand its limitations and apply it wisely.

Structural design for railway stations and auxiliary structures (such as pedestrian overpasses, railway workshops, and utility tunnels) has also begun to benefit from the AI wave, although the extent of application is not yet as widespread as in the bridge sector. Railway infrastructure projects are often large in scale and require multi-disciplinary coordination (structural, architectural, MEP, operations…). Therefore, AI is expected to act as a comprehensive “digital assistant”, supporting everything from planning to detailed design.

One promising direction is the use of AI in combination with Building Information Modeling (BIM) to create digital twins of stations. These digital twins are virtual models containing complete data on structure, architecture, equipment… and can learn from real-world operational data. According to McKinsey, AI-powered digital twins can optimize infrastructure design and construction—for instance, by proposing station layouts that ensure functionality while shortening schedules and reducing costs. Although this is still in the pilot phase, the potential is promising: future stations could be co-designed by AI and engineers, with AI rapidly simulating the impact of each design decision on operation, safety, and cost—helping the project team make the best choice.

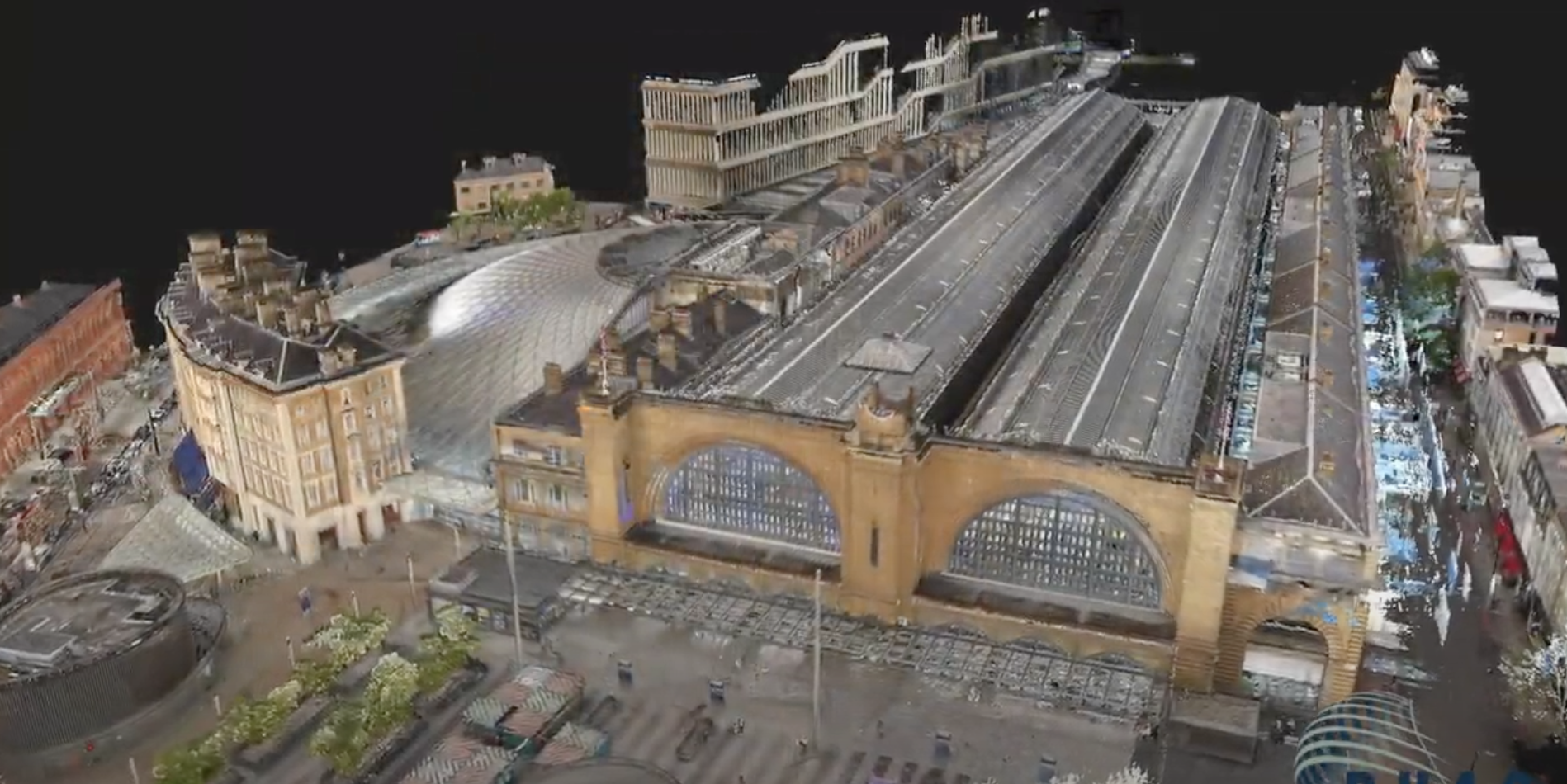

King’s Cross Station, London – UK – uses BIM and AI to create digital twins for structural monitoring, crowd behavior analysis, and maintenance prediction. (Source: RUAS)

In addition, AI-driven big data analysis is being used to improve the design of ancillary structures. For example, AI systems can analyze passenger flow and train boarding times to propose optimal layouts for pedestrian bridges and waiting areas, reducing congestion while saving materials. AI also helps optimize the structural design of large station roofs, especially when combined with parametric design: machines can test thousands of roof shapes and truss systems to find solutions that balance architectural aesthetics with structural performance. These tasks would be time-consuming if done manually, but AI handles them quickly with data-backed outputs.

However, it’s important to acknowledge that AI in railway infrastructure design is still an emerging trend, not yet mainstream. Many AI applications in the railway sector currently focus on operations and maintenance (such as train scheduling and predictive maintenance) rather than structural design. That said, pilot projects have already demonstrated AI’s value in design. For instance, AI can suggest station structures that meet both technical and passenger comfort criteria—something that usually requires multiple feedback loops between structural engineers and architects. With AI, stakeholders can quickly visualize proposed options with estimated costs and operational efficiency, allowing adjustments from the start. This saves design time and prevents late-stage changes due to unforeseen issues.

Overall, in the field of railway station design, AI is a rising trend with practical potential. Tools like AI-powered digital twins promise smarter design decisions based on data rather than subjective experience. Once these technologies mature, station engineers could spend less time on tedious calculations and more on creative problem-solving, while AI handles simulations and optimization behind the scenes. However, at present, AI’s role remains supportive, and its effectiveness depends heavily on the project owner’s and design team’s readiness to adopt the technology.

In the field of civil and industrial buildings (such as high-rises, factories, commercial centers…), AI’s involvement in the structural design process has become increasingly clear—especially through AI-integrated design software and automated design systems. Tasks that are repetitive and time-consuming for structural engineers—like slab and beam layout, bracing arrangement, or foundation scheme calculation—can now be largely automated with AI assistance.

A notable example is DAISY – an AI-powered timber structural design software. DAISY is promoted as the world’s first AI-based timber design tool. In less than 10 minutes, DAISY can produce an optimal timber floor design compliant with structural standards, saving engineers 2–3 working hours per day and reducing up to 80% of timber waste. According to the 2021 report by Autodesk & Daisy AI, DAISY (along with Autodesk’s Kratos AI tool) successfully designed a residential timber floor in the UK that was built in real life. This is clear proof that AI can generate real-world-applicable structural solutions—not just theoretical results. DAISY uses genetic programming algorithms to “evolve” structural floor plans from a given architectural layout, undergoing generations of trial–selection–mutation to find the most cost-effective and durable solution. The final output provides engineers with detailed design drawings, a component list, and material estimates—ready for construction. Importantly, every calculation made by DAISY complies with current design standards, ensuring that AI-generated solutions are still safe and code-compliant.

DAISY AI in Toronto collaborated with Autodesk’s research team in London to design residential buildings using artificial intelligence. (Source: DAISY AI)

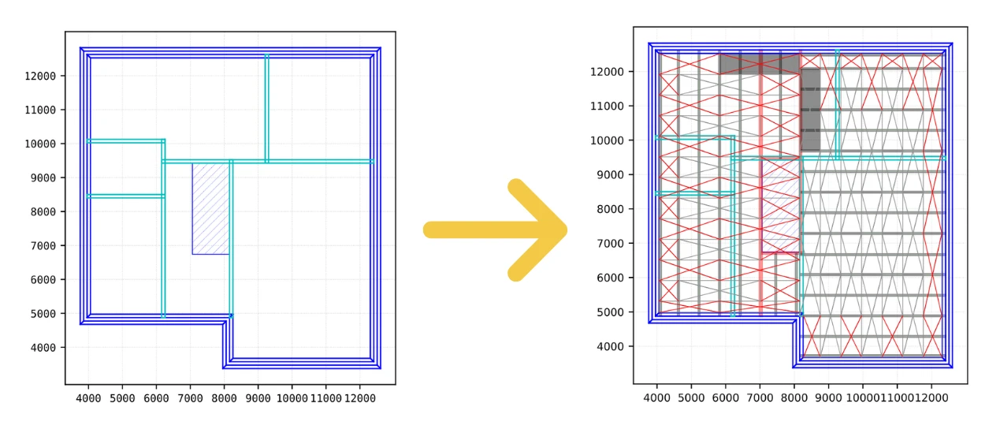

DAISY AI software designing timber floors. From a blank architectural layout (left), the AI automatically arranges joists and trusses (right, red elements) within minutes. The proposed structure ensures load-bearing capacity while optimizing the number of beams and secondary materials compared to manual designs. (Source: DAISY AI)

Beyond DAISY, many traditional structural design software tools have added AI capabilities to assist engineers. For example:

Other platforms like RFEM, SCIA Engineer, and Robot Structural Analysis are also adopting AI optimization modules and BIM integration for streamlined design–analysis–review workflows. These tools help enhance both design accuracy and efficiency: AI can quickly propose optimal beam–column schemes for engineers to check and refine, instead of manually testing multiple assumptions.

However, applying AI in real-world civil/industrial building design still faces some limitations and challenges. On one hand, many so-called “AI” features in software are essentially traditional optimization algorithms or workflow automation—not truly intelligent, learning-capable AI. On the other hand, blindly trusting machine suggestions can be risky if engineers don’t understand the underlying mechanisms. There have been cases where AI proposed fragile or under-redundant designs—statistically sound, but lacking the long-term reliability that seasoned engineers expect. Therefore, human engineering judgment remains the key to validating design quality. AI excels at fast computation and optimization, but only human experience can assess qualitative factors like constructability, maintenance feasibility, or risk contingency.

Overall, AI in civil & industrial structural design is transitioning from trend to reality. Many design firms are already applying AI tools to shorten design timelines, cut costs, and reduce errors—e.g., using AI plugins in Revit to automate drawing extraction. Tangible benefits like 10–15% material savings or design schedules shortened by weeks have been reported in pioneering projects. That said, to fully unlock AI’s potential, the industry must train engineers to master new technologies and develop standardized AI usage guidelines to prevent misuse or misinterpretation of AI-generated outputs.

Structural design for nuclear power plants is a highly specialized field that demands extremely strict safety standards and rigorous verification procedures. Therefore, any new technology (including AI) must demonstrate absolute reliability before being applied. That said, AI is gradually being explored by major nuclear corporations to accelerate plant design and construction—while still complying with strict regulations.

In terms of core structural design (e.g. underground concrete structures, containment walls, shielding tanks…), AI is expected to support engineers in rapidly analyzing thousands of abnormal load scenarios (such as extreme earthquakes, impacts, explosions, etc.). Traditionally, engineers select a few representative load cases for calculation, but AI can learn from simulation datasets to identify the most critical scenarios, minimizing the risk of oversight. AI can also optimize reinforcement layout and structural load paths in key components (such as reactor domes) to ensure they withstand severe incidents while still optimizing material costs. Though information remains limited due to the sensitive nature of the industry, initial research reports suggest that AI can cut months off the design schedule by automating many simulation tasks.

One example is presented at the SPIE Conference “Digital Twins, AI, and NDE” (Non-Destructive Evaluation), where the talk titled:

“Inspection of Concrete Structures in the Nuclear Industry: an AI Perspective” (SPIE 13438 04, 2025) by Rahmat Ali – Canadian Nuclear Labs, discussed the use of Digital Twin and AI in monitoring concrete structures, utilizing sensor data and non-destructive testing methods (NDE) to detect cracking and degradation.

However, it’s important to emphasize that AI in nuclear structural design is still in its early and cautious stage. Any AI-generated proposals must undergo stringent review by experts and nuclear safety authorities. Due to the sector’s “safety-first” principle, AI is primarily used to support decision-making and accelerate non-safety-related processes—not to autonomously make final design decisions. For instance, AI might suggest reinforcement layouts for blast-resistant walls, but nuclear structural engineers will thoroughly evaluate and may apply safety factors exceeding AI’s recommendations.

From a trend perspective, AI is undeniably a critical tool to accelerate and reduce the cost of building future nuclear plants—especially in the case of Small Modular Reactor (SMR) designs, which many countries are now pursuing. But for now, perhaps AI’s most visible contribution is in standardizing and optimizing design–construction workflows—as exemplified by Westinghouse, which is turning reactor construction into modularized assembly lines. This is not science fiction—it’s already being implemented in specific projects.

Currently, regulatory bodies like the ONR (UK), CNSC (Canada), and US NRC are collaborating to develop a regulatory framework for AI in the nuclear sector, particularly focusing on AI safety guidelines and defining three main categories of AI deployment opportunities:

From the analysis above, it’s clear that AI in structural design is no longer a distant future—it is already bringing tangible benefits across multiple sectors. However, the level of “practicality” of AI varies depending on the application domain and approach:

In conclusion, AI in structural design is both an emerging trend and a growing reality. It is not a miracle that replaces humans, but rather a powerful assistant that helps us design faster and smarter. Our role is to adopt AI proactively, capitalize on its strengths, while applying our engineering experience to manage risks effectively. Only then can AI evolve from a buzzword into a practical asset, contributing to safer, more sustainable, and more efficient structures in the future.