High-speed railway (HSR) is becoming a global trend in transportation infrastructure development, offering fast and efficient connections between economic hubs and major cities. For countries like Vietnam, which are developing longitudinal transport corridors, HSR provides solutions for urban connectivity, easing pressure on aviation and road networks, reducing emissions, and enhancing regional competitiveness.

At its core, the high-speed railway (HSR) relies on civil works—subgrade, bridges and viaducts, tunnels, and stations—that must meet exceptional standards of safety, reliability, and sustainability under diverse geological, topographical, climatic, and urban conditions. Beyond the procurement of modern rolling stock, the focus lies in building a robust infrastructure system that meets the strictest technical requirements. Structural design and consultancy thus play a decisive role, ensuring the safety, efficiency, and durability of the entire project.

This article, based on Pontech’s experience and perspective, provides an in-depth analysis of the key structural components, essential design principles, and the opportunities and challenges that engineers must address in such projects.

1. Overview of High-speed Railway

A high-speed railway is defined as a railway system with a minimum operational speed of 250 km/h, applying a unified configuration of infrastructure, rolling stock, and specialized signaling.

As a strategic mode of transport, HSR relieves pressure on highways and aviation, promotes regional economic growth, and rapidly connects major urban centers. Investment in HSR reflects a nation’s commitment to modern infrastructure, aligning with the trends of developed countries.

A high-speed train running from Beijing to Guangzhou over the Yongdinghe Bridge.

The core principles of HSR structural design require a zero-defect mindset: risk control from the selection of design codes, load models, and track geometry to dynamic analysis, rail–structure interaction (RSI), tunnel aerodynamics, and seismic impacts. The concept of Life-Cycle Cost Assessment (LCCA) is applied throughout—prioritizing structural configurations, materials, and construction methods that minimize life-cycle costs (CAPEX + OPEX), instead of focusing only on initial investment.

2. Key Structural Components and Technical Challenges

From a structural perspective, the main components of a high-speed railway line include the superstructure (rails, sleepers, and ballast or concrete slab track) and the substructure (subgrade, bridges/viaducts, tunnels, and stations). These civil works bear the direct loads from trains and represent the core of any HSR project, where structural engineers demonstrate expertise and innovation.

2.1. Subgrade, Rails, and Sleepers of High-speed Railway

The subgrade supports the track system (rails, sleepers, and ballast or slab), distributing train loads to the natural ground while maintaining track geometry, stability, and drainage.

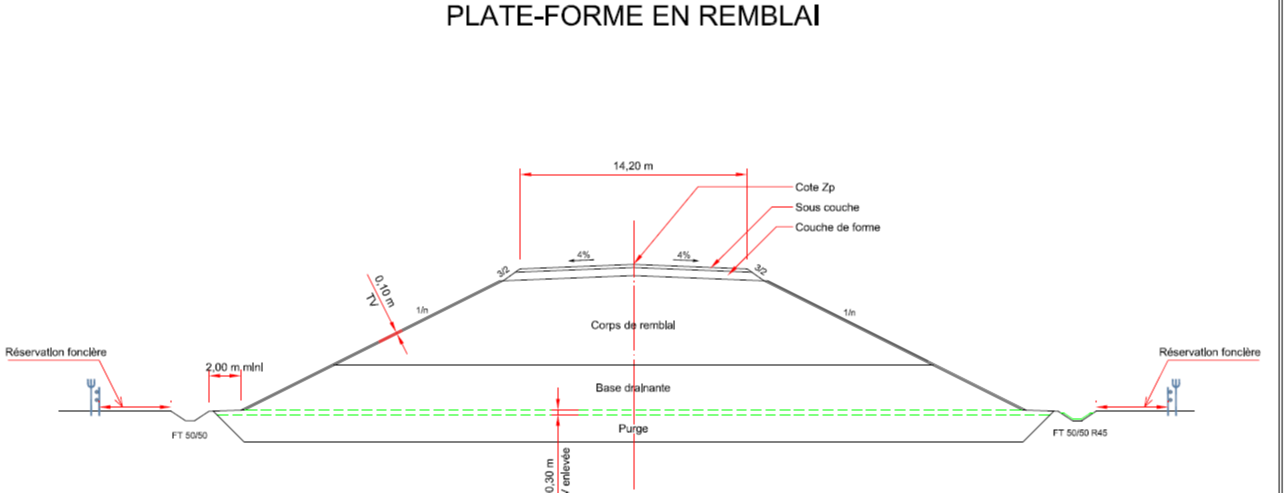

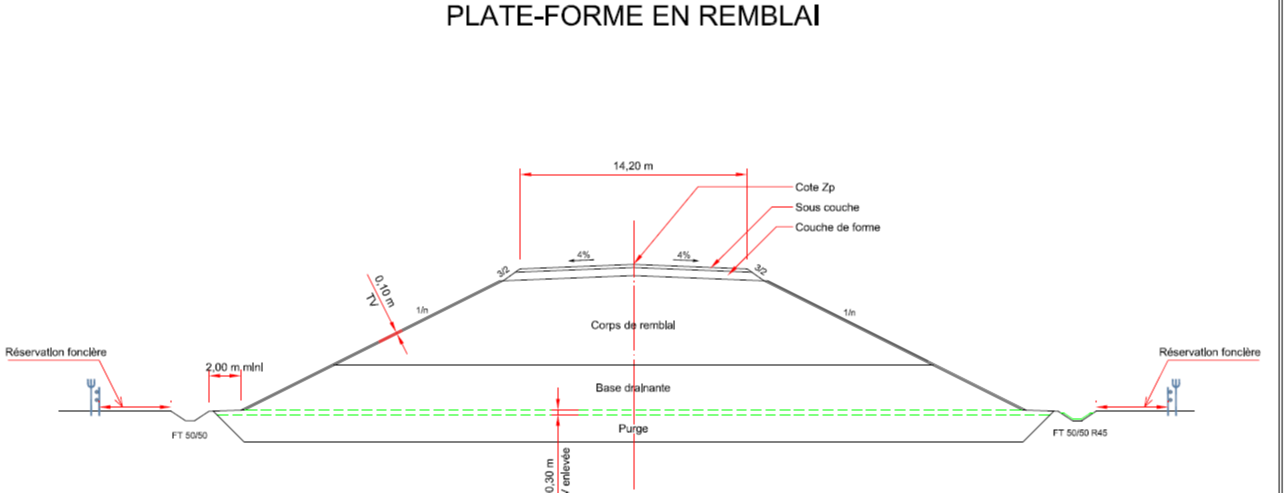

Typical cross-section of an embankment subgrade in HSR design.

HSR subgrade after construction of embankment and capping layer.

- Subgrade: HSR subgrades require special treatment to ensure stability and prevent settlement. Natural soil is compacted with selected materials, topped with capping layers that distribute loads from ballast or slab track. Settlement control is a critical challenge, especially in Vietnam with its complex terrain and soft soil regions.

-

Rails and Sleepers: Unlike jointed rails, HSR uses continuous welded rails (CWR) many kilometers long, eliminating joints and ensuring smoother rides with less vibration and noise. Sleepers are specially designed to secure rail positions under high speeds and dynamic forces.

-

Ballasted Track: The traditional system, where ballast distributes loads from sleepers to the subgrade.

-

Ballastless Track (Slab Track): A key technology that replaces ballast with reinforced concrete slabs. Its construction requires millimeter-level precision over kilometers, but provides superior stability, minimal maintenance, and extended service life.

This image illustrates subgrade, rails, and sleepers in a high-speed railway system under construction.

2.2. High-speed Railway Bridges and Viaducts

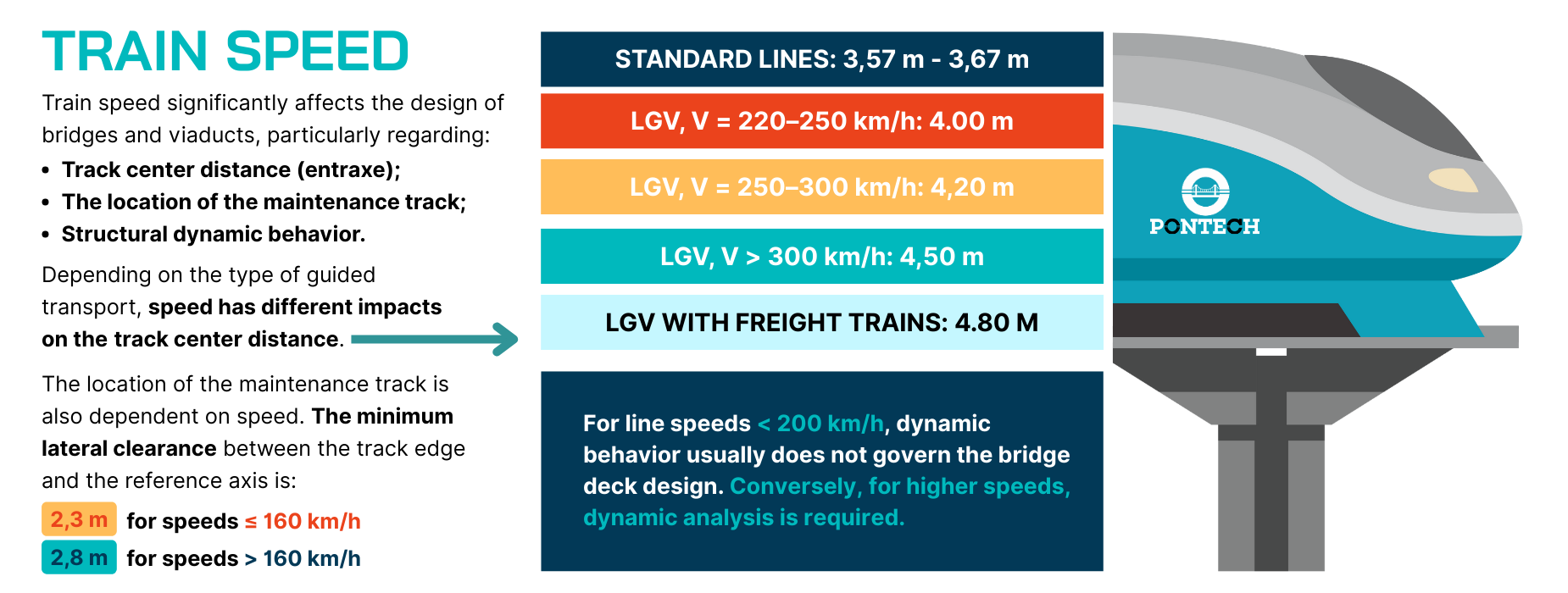

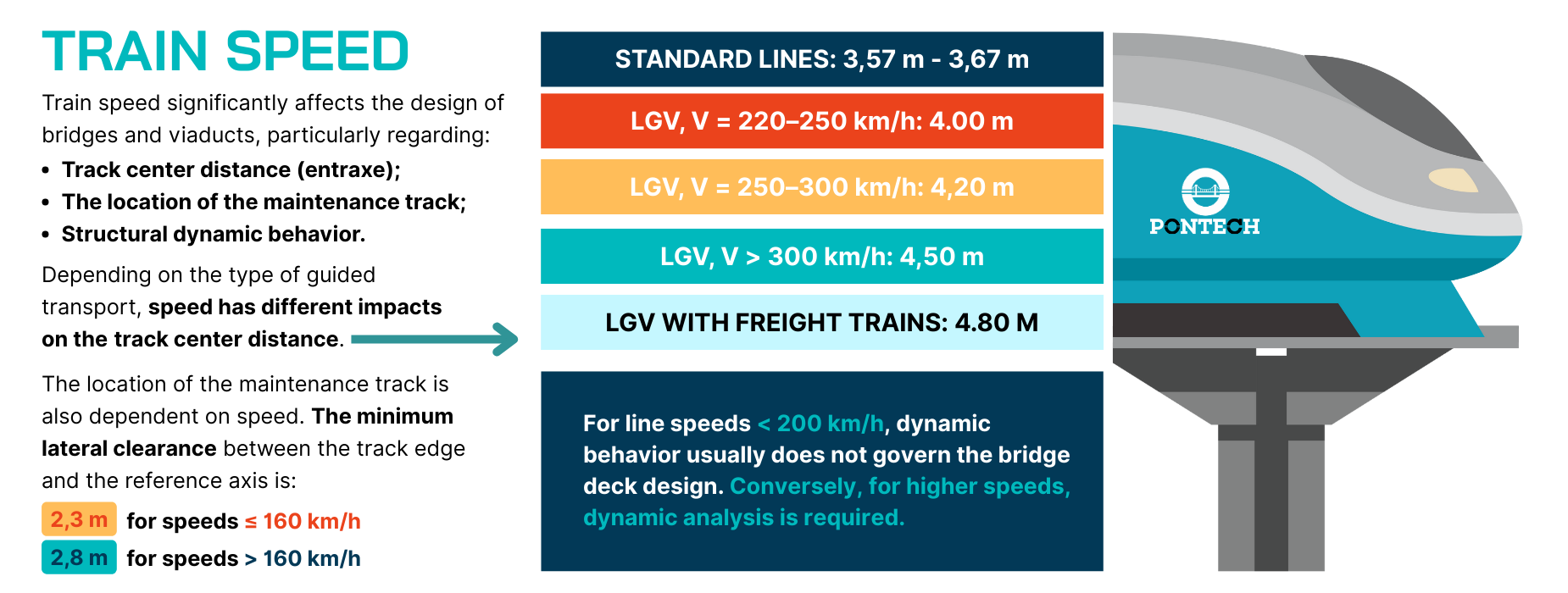

Bridges and viaducts often account for the majority of HSR alignment, posing some of the most complex structural challenges. Design must consider clearance (gabarit), track spacing (entraxe), maintenance walkways, parapets, drainage, wind barriers, noise walls, grounding, and cable protection.

Common structural solutions include:

-

Prestressed concrete (PSC) box girders with segmental construction.

-

Prestressed I-girders with cast-in-place decks.

-

Precast box girders launched with launching gantry technology.

Choice depends on terrain, schedule, girder fabrication logistics, deck width, load requirements, and dynamic behavior. Critical checks include natural frequencies, longitudinal/lateral stiffness, bearings, anti-slip devices, and expansion joints—evaluated for long-term serviceability and special states.

Join Pontech to explore how speed impacts the design of high-speed railway bridges and viaducts!

The Impact of Speed on Bridge and Viaduct Design.

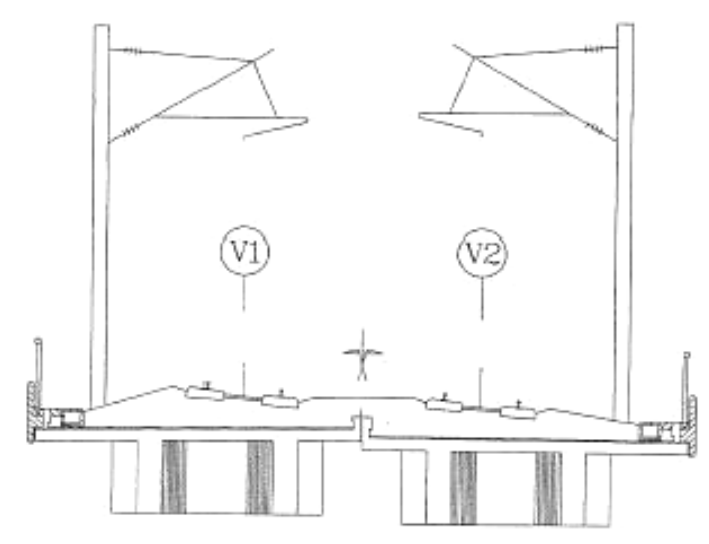

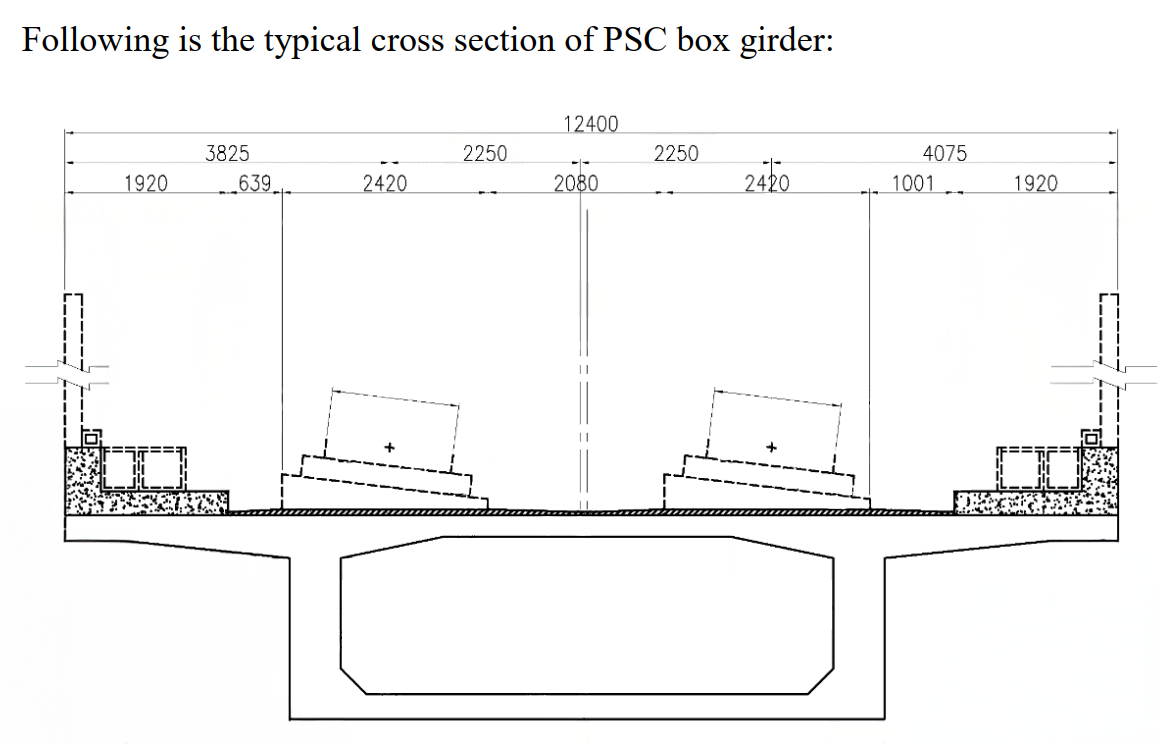

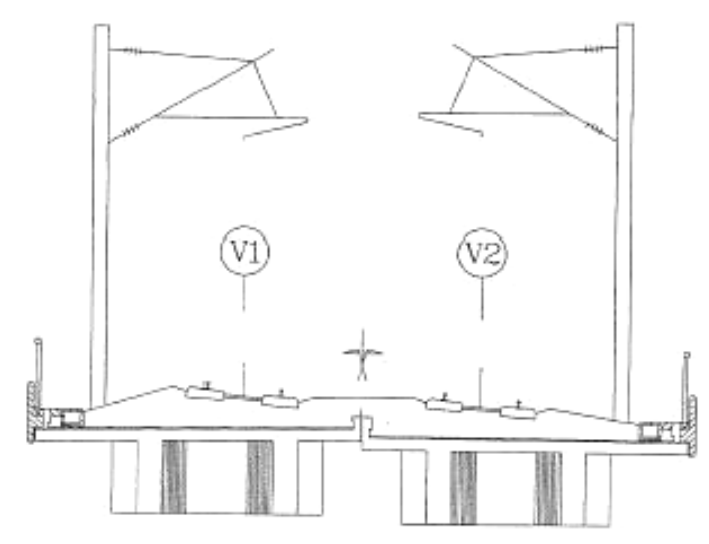

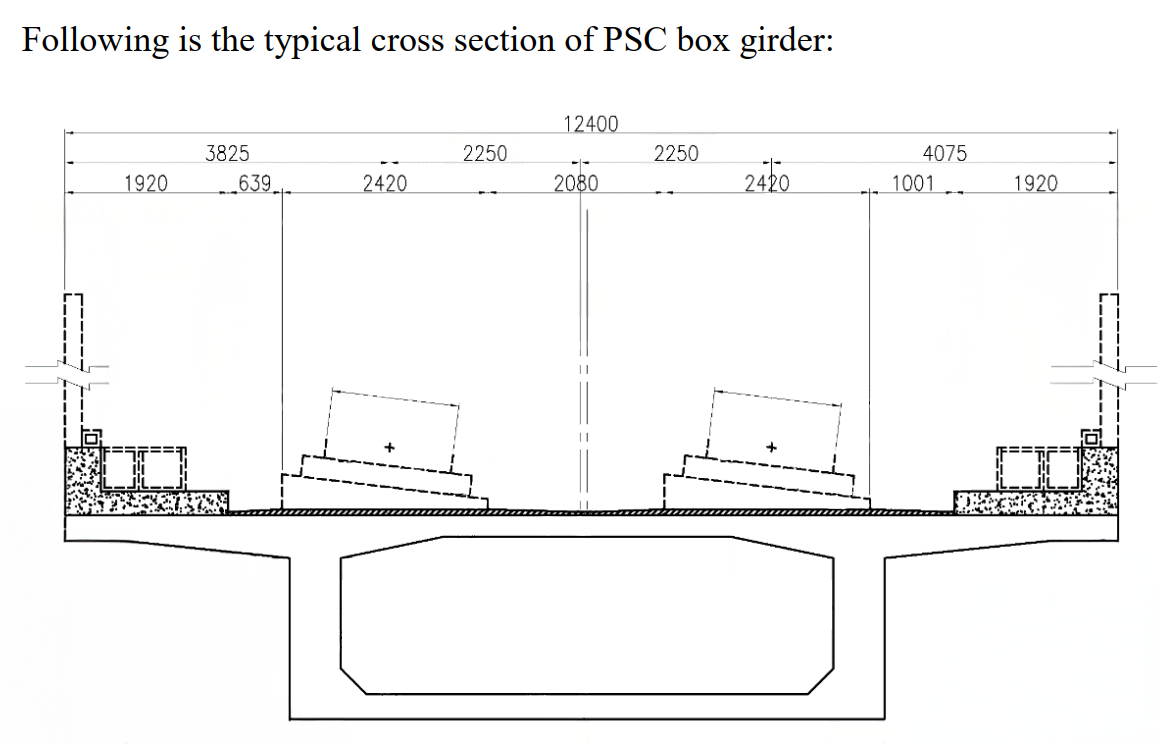

Examples of cross-sections of high-speed railway bridges:

Cross-section of an I-girder for HSR bridge.

Cross-section of a PSC box girder for HSR bridge.

Key technical challenges:

-

Train Load Effects: HSR bridges must resist far greater loads than road bridges, including dynamic impacts from high-speed trains.

-

Train–Bridge Dynamic Interaction: Passing trains induce vibrations and deformations. If resonance occurs, it may compromise stability and passenger comfort. Advanced dynamic analysis is required.

-

Rail–Structure Interaction (RSI): Continuous welded rails running across multiple spans generate additional stresses due to temperature, braking, and deck-rail connections. Proper design avoids excessive rail stress or damage.

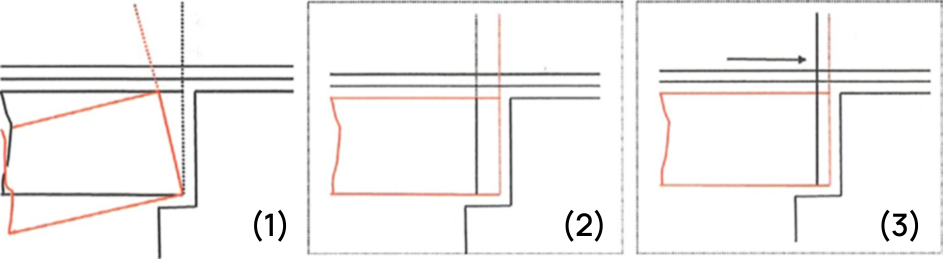

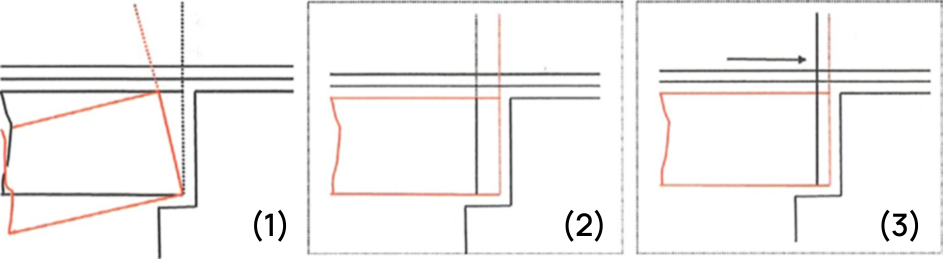

Illustration of three RSI phenomena near bridge abutments.

In addition, for high-speed railway bridges, specific serviceability limit states (SLS) must be verified. These limit states are not related to the strength or durability of the structure but rather to the safety and comfort of railway operations on the bridge. This concept is almost absent in road bridge design, which generally only requires checking vertical deflection under traffic loads (and in some cases, this is not even mandatory).

The serviceability limit states to be checked for high-speed railway bridges include:

- Vertical acceleration of the bridge deck (related to both safety and passenger comfort).

- Deck torsion per unit length, i.e., angular twist variation per meter of deck length (related to safety).

- Longitudinal displacement of the deck (related to safety).

- Vertical deflection and lateral deformation of the deck (related to both safety and comfort).

From the above, readers can better understand the unique technical requirements in the structural design of high-speed railway bridges.

2.3. High-speed Railway Tunnels

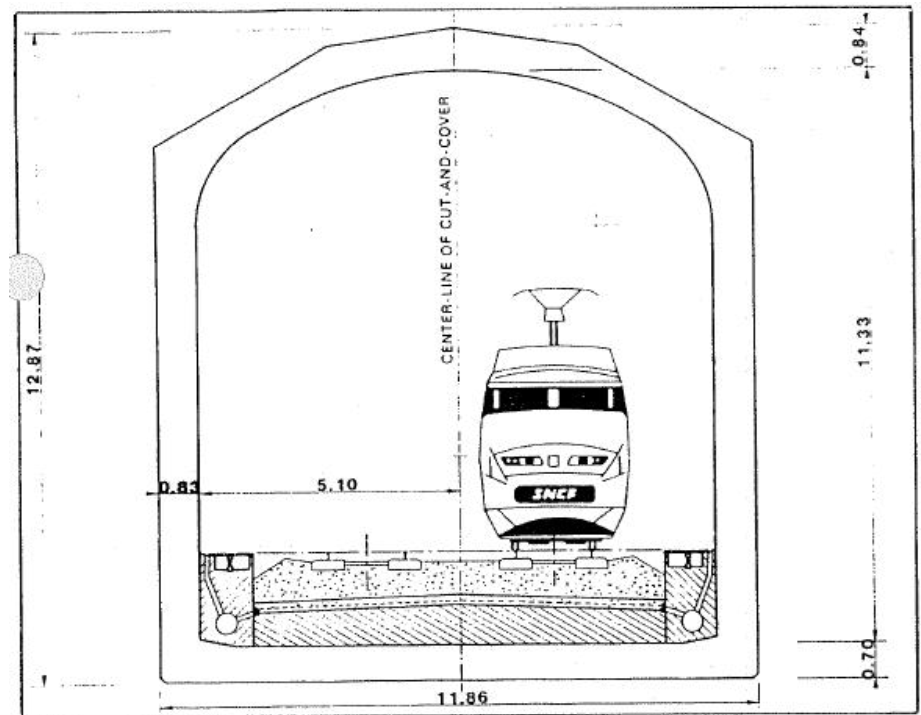

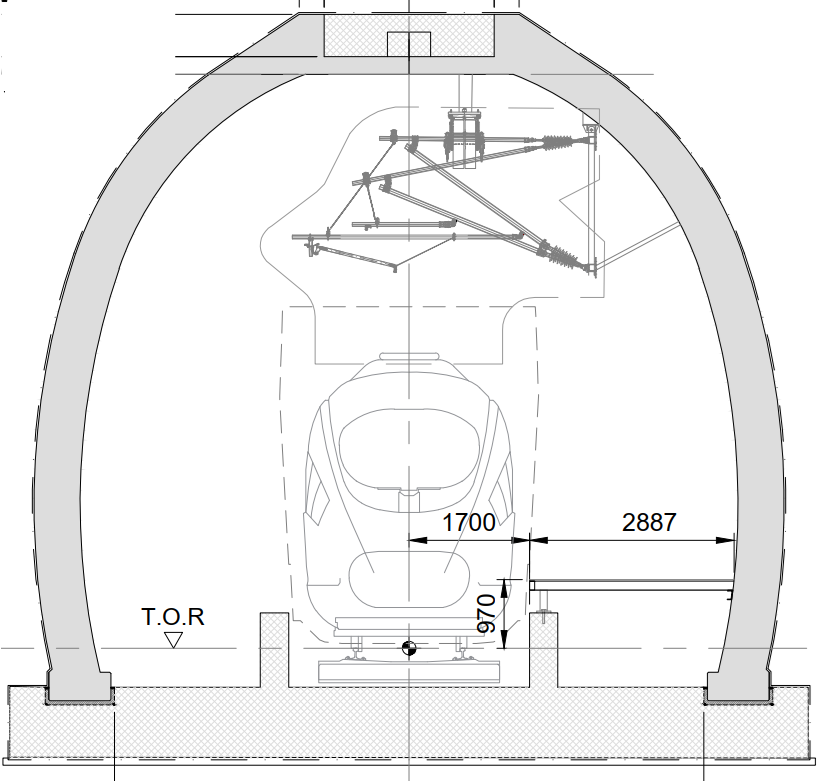

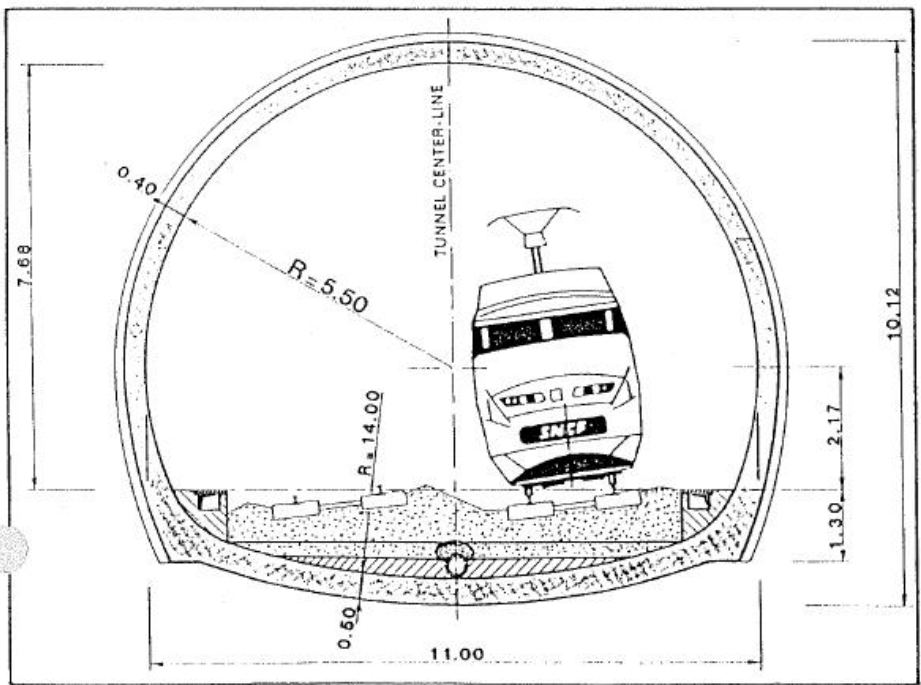

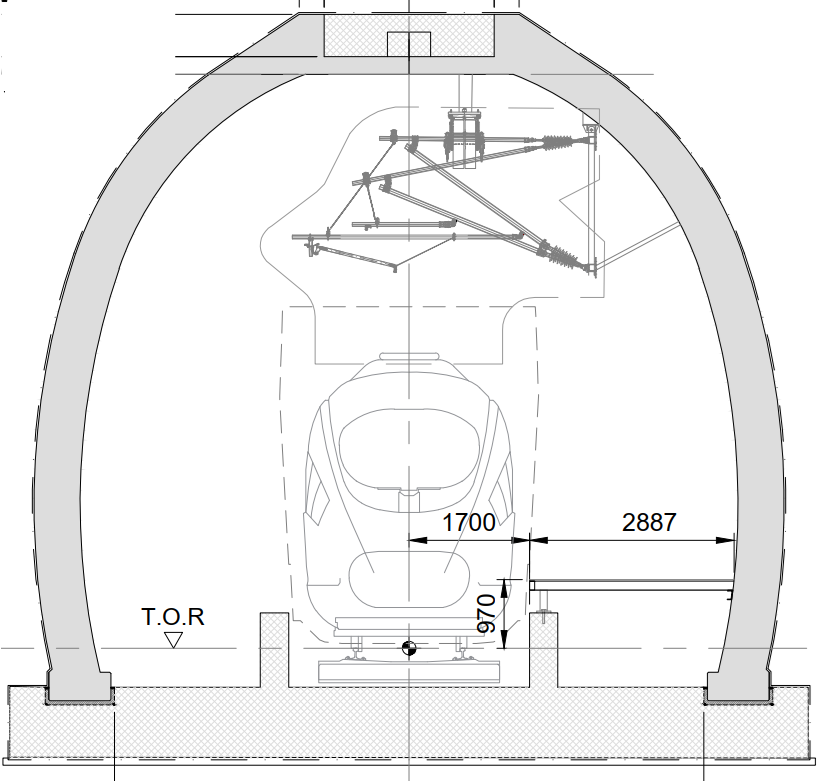

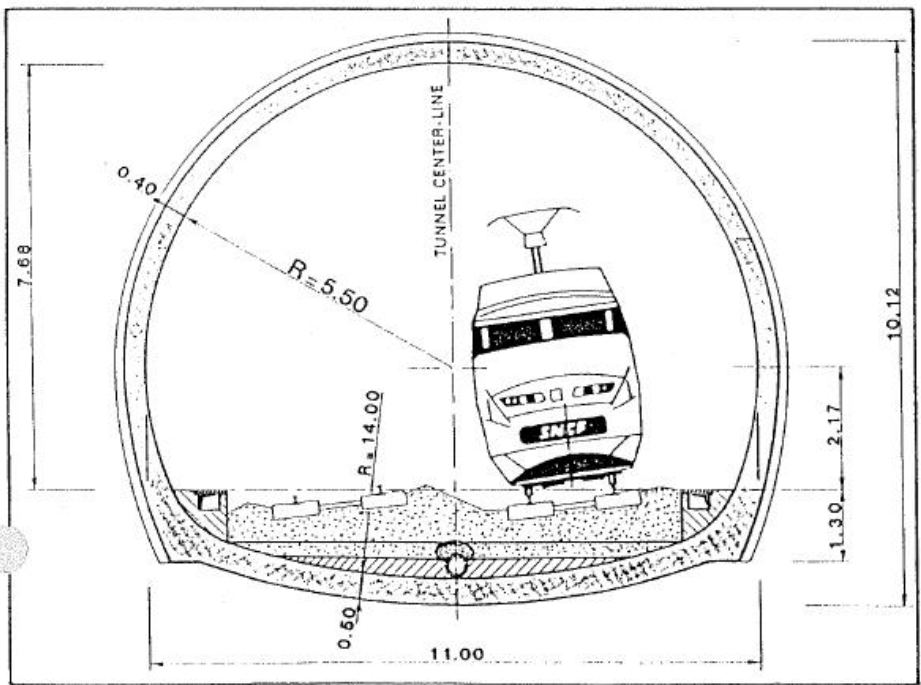

High-speed railway tunnels require strict control of micro-pressure waves, pressure surges when trains enter/exit the tunnel, ventilation and emergency evacuation, waterproofing and longitudinal drainage, as well as lining durability.

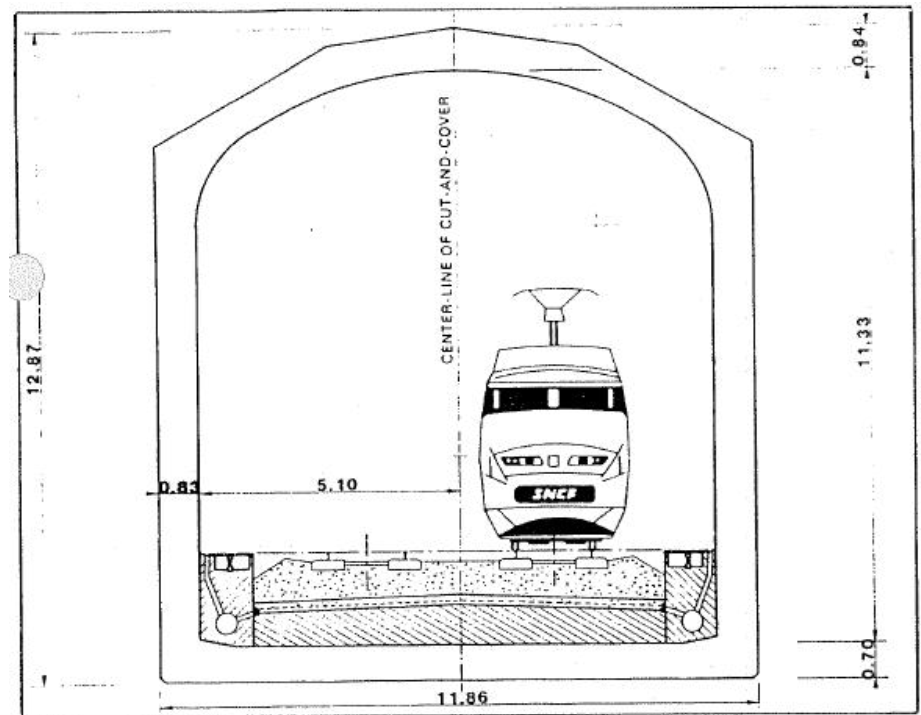

Tunnel structure: The tunnel lining must not only resist earth and rock pressures but also ensure absolute watertightness—an enormous challenge in complex geological conditions and groundwater environments. The choice of construction method—cut-and-cover, TBM, or NATM—depends on geological factors; in urban areas, settlement control and the interface between tunnel–station–viaduct must be carefully managed. The geometric precision of the tunnel alignment directly affects ride comfort at high speeds.

There are three possible tunnel cross-sectional shapes:

-

Rectangular, used where pressures and loads are low

-

Vaulted, used where pressures and loads are moderate

-

Circular, used where pressures and loads are high

-

-

Rectangular (low pressure, light loads)

-

-

Vaulted (medium pressure, moderate loads)

-

-

Circular (high pressure, heavy loads)

2.4. High-speed Railway Stations and Auxiliary Structures

High-speed railway stations are not merely stopping points but complex architectural and engineering facilities, often designed under the Transit-Oriented Development (TOD) model.

Station design focuses on passenger flow, fire safety, and large-span structures (steel roofs, prestressed concrete frameworks). Special technical considerations include buffer space arrangement, track gauge (gabarit), platform elevation and longitudinal gradient, as well as large expansion joints at tunnel–viaduct transitions—all of which present significant structural design challenges unique to HSR stations.

Foshan West Station serves high-speed trains (CRH) within China’s high-speed railway network.

Key Auxiliary Structures:

-

Depots and Maintenance Workshops: These facilities handle the maintenance and repair of locomotives and rolling stock. Their structural design must meet requirements for heavy load capacity, wide spans, and special standards for crane systems and lifting equipment.

-

Traction Substations: High-speed railway systems operate on high-voltage direct or alternating current (typically 25 kV). Substations, overhead catenary lines, and related facilities must be arranged in strict compliance with technical safety standards.

3. Emerging Technologies in High-speed Railway Structural Design

-

Industrialized Construction: Standardization of structural components, use of precast concrete technology (girders, modular piers), rapid assembly, and uniform quality control.

-

Precast Spans + Precast Slab Track: Accelerating construction schedules through industrialized solutions.

-

BIM–Digital Twin–SHM: Real-time data analysis, condition-based maintenance (CBM), and OPEX optimization. Digital Twins—virtual models of the entire system—enable engineers to simulate, predict failures, and optimize maintenance strategies, already adopted in HSR networks in China, Japan, and Europe.

-

Data Standardization: Implementation of CDE (Common Data Environment), standardized naming conventions, metadata protocols, and dashboards for cost–risk–schedule monitoring.

-

Next-generation Materials (UHPC, FRP, protective coatings): Enhancing structural durability and protection in aggressive environments, significantly reducing maintenance costs.

-

Generative Design: Applying AI to generate thousands of optimized design alternatives, enabling engineers to identify lighter, more sustainable, and material-efficient structural solutions.

-

Sustainable & Dual-purpose Infrastructure: HSR projects are increasingly integrating recycled materials, renewable energy, and designs that allow combined passenger and freight transport—serving both economic and strategic defense objectives.

These trends illustrate a forward-looking vision, where technology, advanced materials, and sustainable design converge to create a high-speed railway system that is safer, more efficient, and future-ready.

4. Current Development in Vietnam: Projects, Opportunities, and Practical Challenges

4.1. Vietnam High-speed Railway Project

The most significant high-speed railway (HSR) project in Vietnam is the North–South line, connecting Hanoi and Ho Chi Minh City. This is a national flagship project, with groundbreaking targeted for December 2026 and full completion by 2035. The total length of the line is approximately 1,545 km, with a design speed of up to 350 km/h.

Key infrastructure requirements include adaptation to diverse topographical and geological conditions (delta plains, mountainous regions, and coastal areas), resilience to the tropical monsoon climate, and alignment with international technical standards while ensuring compatibility with domestic codes.

It is estimated that about 80% of the route will consist of bridges, viaducts, and tunnels—highlighting the massive structural scope and associated costs. As a result, optimizing the design of these structures to reduce overall costs is essential. This presents major challenges in structural consultancy, requiring the expertise of leading engineering specialists.

One of the two investment options for the North–South High-speed Railway.

4.2. Opportunities for Structural Engineering Experts

-

Participation in a landmark project: This is an unprecedented opportunity for domestic structural consultancy firms to enhance capabilities, adopt advanced technologies, and contribute to a project of national significance.

-

Technology and expertise development: Involvement in the project will drive enterprises to research and apply advanced software for structural modeling and dynamic analysis.

-

Training high-quality human resources: Demand for skilled technical personnel, particularly structural engineers with experience in high-speed railway projects, will grow significantly.

4.3. Major Technical Challenges for Vietnam’s High-speed Railway

-

Technology gap: Mastering new technologies and international standards remains a significant challenge for local engineers.

-

Design standards: Developing a Vietnamese set of HSR design standards that reflects local realities while maintaining compatibility with international codes is a complex task. (For further reference, see the Railway Structural Design Standards here)

-

Geological and environmental factors: Addressing issues of soft soil, seismic risks, and climate change impacts poses unavoidable technical challenges.

However, despite these major challenges, Vietnamese engineers have already demonstrated their capabilities on the international stage. Specifically, engineers from Pontech, a company led by Vietnamese experts, have contributed to several international high-speed railway projects:

In addition, Pontech’s engineering team has participated in numerous large-scale projects in the fields of bridges, viaducts, and railway infrastructure. Their international experience allows them to master complex processes, technical standards, and project management requirements. Core competencies include the design of HSR bridges and viaducts (prestressed concrete box girders, U-girders, precast I/Box girders, dynamic analysis, and Rail–Structure Interaction (RSI)), slab track design for bridges, tunnels, and subgrades, as well as large-span station design integrating MEP, fire safety, and signaling systems. Readers can explore more at Pontech’s Services page.

This demonstrates that Vietnamese engineers possess the expertise and experience required to participate in highly complex high-speed railway projects.

5. Conclusion

High-speed railway is a strategic engineering endeavor that demands precision and advanced expertise in every stage of structural design and consultancy. From subgrades, bridges, and tunnels to stations, each component must comply with stringent standards to ensure safety, stability, and long-term sustainability. The North–South High-speed Railway project represents a major opportunity for domestic consultancy firms to strengthen their capabilities, adopt advanced technologies, and contribute to the nation’s development.

With a clear vision and deep technical expertise, companies like Pontech are ready to be trusted partners in building resilient and safe high-speed railway infrastructure for the future.

Discover more about Pontech’s high-speed railway bridge, station, and auxiliary projects, or contact us for tailored design solutions that meet international standards.

↪️ Contact Pontech here!